Agriculture Reference

In-Depth Information

the threshold for injection be matched carefully

to the viscosity of the compound. The behaviour

of hemp-reinforced polymers is clearly pseudo-

plastic.

Natural fibres contain a certain amount of

pectin, which is degraded at temperatures in

excess of 160°C. This can confer a light brown-

ish colour to products without their properties

being affected. That said, a dark brown colora-

tion together with a strong-smelling product

indicates that the transformation conditions

are maladjusted.

When conducting initial tests, it is rec-

ommended that the compounds be diluted to

obtain a fibre concentration of approxi-

mately 20%. This approach allows materials

to be transformed without there being a risk

of degradation and allows operators to

familiarize themselves with the use of the

compound.

14.4 Applications

14.4.1 Plastics

Plastic materials reinforced with hemp fibres

are used in all the main plastic markets (Figs

14.13-14.17).

14.4.2 Unwoven felt

Natural fibres have been used by the automo-

bile industry for more than a decade in the

creation of car interior fittings. The products

are made of felt with a density of approximately

500-2000 g/m

2

. These felts are produced

from a 50:50 mix of natural fibres (hemp, flax,

sisal, jute, kenaf, abaca) and thermoplastic

fibres (typically, PP). The mix is carded and

needled to produce sheets with a thickness of

5-30 mm.

The felt is heated in flat presses to a

temperature approaching 200°C before

being placed in a cold mould. The end prod-

uct is light and rigid and is not brittle. The

manufacturing process only allows the pro-

duction of pieces with a constant thickness

and low stamping rate. The majority of

German and US car manufacturers use these

materials to produce door panels, parcel

shelves and boot panels.

The production of felts with a density of

400-1000 g/m

2

without the addition of syn-

thetic fibres allows sheets to be produced for

use in mulching and soilless cultivation.

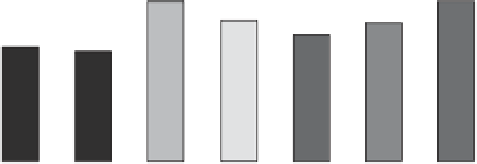

MPa

7000

6000

5000

4000

3000

2000

1000

0

PEhd

PPh

PVCu

ABS

Fig. 14.11.

Section modulus for different polymers

reinforced with 30% hemp fibre.

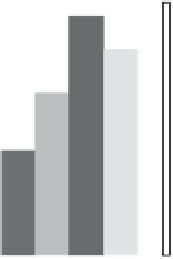

MPa

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0.0

Spruce

Flour

Spruce

Sawdust

Hemp

Sisal

Flax

Jute

Kenaf

Fig. 14.12.

Maximal tension resistance (compounds with 30% plant fibre reinforcement).