Agriculture Reference

In-Depth Information

MG

cylinder

Air drier

Reel

Post-dryer

section

(6 driers)

Pre-dryer section

(16 driers)

Press section

(2 presses)

Fourdrinier

table

Grammage

/ moisture

scanner

Gas heated

cylinder

White water recirculation

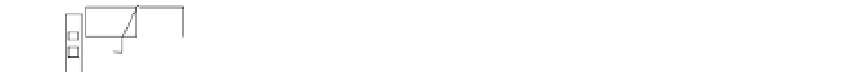

Fig. 13.14.

Diagram of a paper machine.

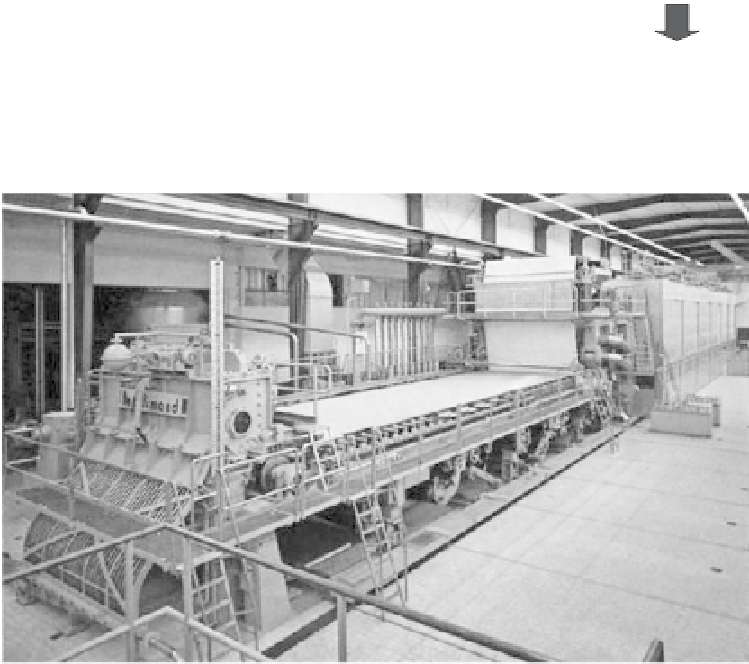

Fig. 13.15.

An industrial paper machine. Foreground: the headbox feeding the fourdrinier table; middle

distance: a vertical press section; background: the drying section.

13.7 Conclusion

preparation is spread on a wire on which the

pulp suspension is dewatered from 3 to 5 g/l

concentration to a wet sheet of 20-25% of dry

matter. This sheet is then transferred on a felt

to the press section to improve dewatering

before moving to the drying section, in which

the water is evaporated on rolls heated to 100-

110°C. The paper is rolled at the end of the

machine and stored before use.

Figure 13.14 shows a diagram of a paper

machine.

An industrial paper machine can produce

10-30 t/day. The wire width is 2-3 m and the

machine speed is 200-300 m/min. Figure 13.15

shows an example of an industrial paper machine.

The use of hemp in papermaking is focused

mainly on cigarette paper production,

because its long and resistant fibres allow the

manufacture of thin paper. The whole hemp

production is devoted to this use, as the whole

hemp plant can be considered for pulp pro-

duction, generating long and short fibres,

which can be used mixed or separate. The

application of long hemp fibres in tissue

paper increases wet resistance, improving

the quality of such products. Development of

the uses of hemp can also be orientated to

non-woven production.