Agriculture Reference

In-Depth Information

A closer estimate of the future market

chances of different NF techniques is provided

below.

constitute an exception. Their market share is

still less than 1%, but will increase.

The data for cotton are even sparser. Only

a few hundred tonnes could be verified,

although our previous study (2004) had stated

about 45,000 t of cotton and about 79,000 t

of respective composites for 2003.

This discrepancy was due to the fact that

the survey was conducted primarily among

passenger car subsuppliers, while thermoset

cotton composites today are used almost exclu-

sively in lorry driver cabs.

11.6

Excursus: Wood and Cotton

In the framework of the study, there has been

an attempt to survey also the amounts of wood

fibres and cotton that are used in German

automotive production. Unfortunately, how-

ever, this was not possible in the framework of

the investigation.

As important companies from the wood

fibre and wood flour processing sector did not

take part in the survey, merely about 16,000 t

of wood fibres could be verified. In the frame-

work of our market study of 2004, we had

assumed about 25,000 t of wood fibres and

about 36,000 t of wood fibre composites for

2003. Because growth was generally expected

for this sector, we estimated the amount for

2005 at about 27,000 t of wood fibres and

about 40,000 t of respective wood fibre

composites.

The wood fibre composites used in the

automotive industry have a large fibre con-

tent and an almost exclusively thermoset

matrix. Wood plastic composite (WPC) gran-

ulates made from a thermoplast, wood flour

and fibres, respectively, as well as additives,

11.7 Natural Fibre Shares for

Different Production Techniques

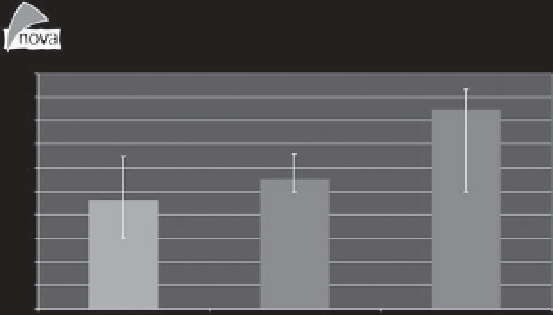

Figure 11.4 shows the NF shares for differ-

ent production techniques. This year, as

mentioned in the introduction, these data

were surveyed for the first time. As expected,

the fibre shares for thermoset wood com-

posites were the highest with just under

85%. When natural fibres (not including

wood and cotton) are processed on a ther-

moset basis, the fibre share amounts to

approximately 55%. The large share of NF

in thermoplastic composites came as a sur-

prise. While in the past, in accordance with

the producers interviewed, we had assumed

a fibre share of 30-40%, the current survey

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

46.2%

55.2%

84.7%

Natural Fibres*

Thermoplast

Natural Fibres*

Thermoset

Wood Fibres

Thermoet

* without wood and cotton

Fig. 11.4.

Natural fibre reinforced composites (not including wood or cotton) in different processing

technologies of composites in the German automotive industry in 2005 (nova-Institut, November 2006)