Agriculture Reference

In-Depth Information

was found for a ramie sample (10.7%), while for

Crotalaria

('sunn hemp') a difference of 12%

was observed.

125

100

75

10.3.3 Using density values for

strength calculation

50

Well-documented studies of the mechanical

properties of natural fibre reinforced compos-

ites lead to the conclusion that it is very impor-

tant to know the exact density, because then it

is possible to calculate precisely the fibre volume

content or the cross-sectional area of the fibres

and, subsequently, the composite properties

(Cichocki and Thomason, 2002; Madsen and

Lilholt, 2003). Globally, mechanical notations

for engineered parts are related mainly to the

surface; a common unit is N/mm

2

or MPa. The

measurement of fineness in the textile industry

is usually expressed in tex. This measurement is

convenient for fibre bundles like bast fibres that

do not have circular or nearly circular cross-

sectional areas. The gravimetric fineness meas-

urement method described above can be carried

out with simple equipment. Generally, a conver-

sion is made using a standard density value

taken from the literature. The disadvantage is

that no reliable data for calculation can be

achieved.

An accurate measurement can be

obtained by analysing the density of the sam-

ple. In this case, the volume of the lumen and

porosities will not be considered. This allows

a proper conversion from a mass-related to a

surface-related mechanical property. This

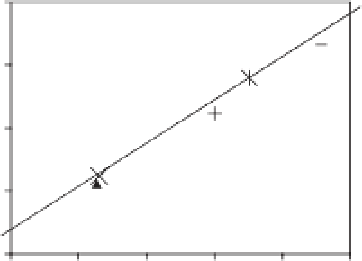

can be confirmed by the results of single-

element tensile tests realized with the auto-

mated miniature tensile tester Dia-Stron

plotted in Fig. 10.11. The mechanical values

and the cross section were measured for

each fibre type. The measured density was

used to calculate the mechanical strength in

cN/tex. The line shows the calculated mass-

related density values using a standard liter-

ature density of 1.45 g/cm

3

. A proper

conversion from mass-related values into

surface-related ones is not possible if only

such standard density values are available.

For materials with densities >1.45 g/cm

3

(e.g. lyocell, ramie), the surface-related

25

500

750

1000

1250

1500

1750

Strength, N/mm

2

Lyocell

Jute

Sisal

Flax A

Cotton

Flax B

Hemp

Ramie

Fig. 10.11.

Fibre tensile strength in terms of linear

density (cN/tex) versus a surface-related strength

(N/mm

2

)/single-element strength tests using

Dia-Stron.

mechanical properties will be underestimated.

For materials with lower densities (e.g. sisal),

the opposite is true.

10.3.4 Mechanical properties of natural

and man-made cellulose fibres

It has been shown that the mechanical proper-

ties of natural fibres are competitive with those

of glass fibres, especially as short fibre rein-

forcement in composites (Schwill

et al

., 2004).

Table 10.5 summarizes the mechanical values

of the tested fibres and fibre bundles. At first

glance, the wide distribution of the mechanical

values does not seem to allow any calculation

of the mechanical properties of, for example,

composites. In case of the bast fibre samples,

flax and hemp, the standard deviations (not

shown here) of strength and Young's modulus

are equal to or bigger than the mean values.

The reason for the wide strength distribu-

tion lies in various natural defects and prop-

erty variation. Ruys

et al

. (2002) observed in

plant fibres natural defects like cracks, holes,

regions of reduced cross-sectional area, dislo-

cation bands and miscellaneous irregularities

in shape. They point out that the breaking

operation results in a high level of defects in

individual fibres. The presence of these defects