Agriculture Reference

In-Depth Information

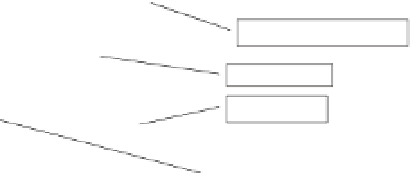

We will also present two further fibre

extraction processes: the turbine process and

extraction by steam explosion.

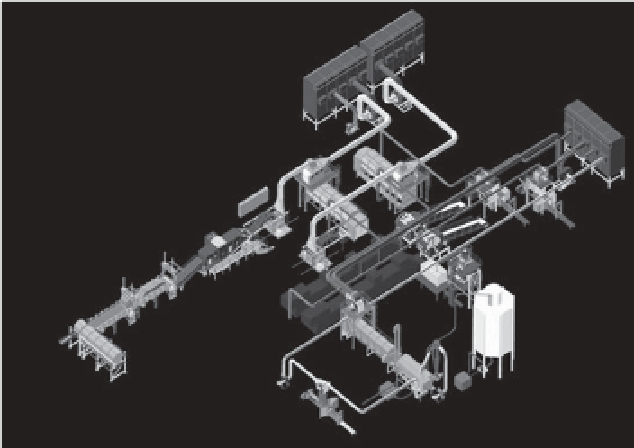

Having summarized the main steps of the

fibre extraction process, and in order to

illustrate the industrial production line, we will

present an example, that of Van Dommele-

Laroche (Fig. 9.6).

This illustration will now serve as the start-

ing point for a description of the most com-

mon fibre extraction process.

possible. A blower or aspirator may be

used to eliminate further dust and foreign

objects.

METAL DETECTOR

.

In general, at this stage of

straw processing, some sort of metal detec-

tion is used. Most commonly, the elimina-

tion of metal must be undertaken manually,

but systems also exist that allow the suspect

item to be redirected towards an outside

stock.

GUILLOTINE

.

The hay bale (with a diameter of

1.65 m and a weight of approximately 380 kg)

is placed on the belt and conveyed to the 'guil-

lotine'. This consists of a horizontal, hydrauli-

cally powered blade that cuts the straw into

pieces 30-50 cm in length (for other methods

of cutting straw, see box 9.5).

CRUSHERS

.

This is the heart of the fibre extrac-

tion process. Three main devices are used. As

shown in Fig. 9.6, two hammer crushers are

installed in order to ensure that the fibre is

cleaned as thoroughly as possible.

HAMMER CRUSHER

.

In order to reproduce the

mechanism of the old crushing machinery,

whose function was to crush the straw, a sys-

tem was designed that projected the straw

pieces on to a fast revolving cylinder, equipped

with mobile hammers.

The projected straw is caught in the space

between the cage and the cylinder. The ham-

mers are brought down on to the straw by

LOADER OR PRE

-

OPENER

.

The chopped straw

falls on to an inclined belt, which takes it to a

loader. The loader's role is to:

eliminate by gravity, stones and other

•

undesirable foreign objects;

spread out the straw into a bed that is as

•

homogeneous and as even in thickness as

Fibre cleaning No 2

Dust filtering

Dust filtering

Fibre cleaning using

Duvex1

Hammer crusher No 1

Cleaning and stone removal N°1

Press for cleaned hurds

First opener

Guillotine N°2

Press for loaded hurds

Hurds press

Guillotine N°1

Hurds silo

Bale convevor

Duvex for cleaning the hurds

Hammer crusher

N°2

Refinement line N°1

Refinement line N°2

Removal of very

small fibres

Press for short fibres

Fig. 9.6.

A diagram of the fibre extraction production line, Van Dommele-Laroche.