Agriculture Reference

In-Depth Information

significantly altered after modification with CPAM due to the grafted copolymer as observed

from the TGA. The benefits of this absorbent are that it is highly stable, flexible and easy to

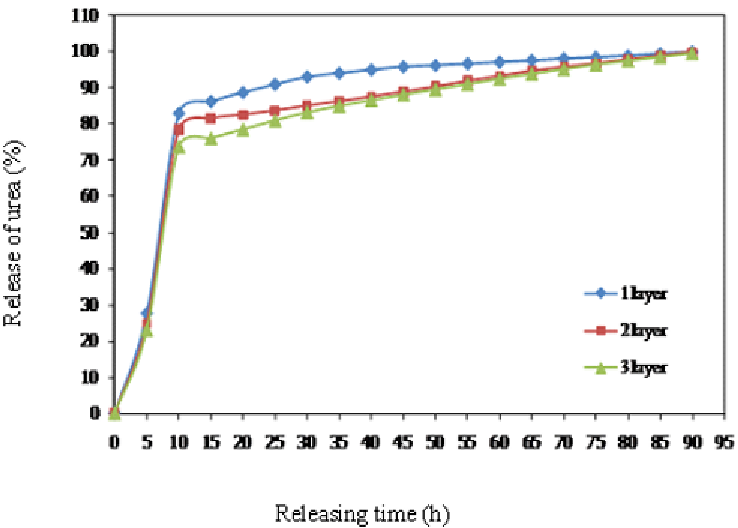

use in the environment. The effect of NR-g-CPAM on the rate of release of urea from the

beads coated with different layers is presented in Figure 32. It is obvious that the rate of urea

release was reduced significantly as a function of the NR-g-PAM coating, which is consistent

with the results of the swelling study. The NR-g-PAM film is very strong, rigid and hard to

swell, so the diffusion through this coating is the rate-limiting step for swelling and release

from the NR-g-CPAM. Using additional NR-g-CPAM layers on the capsule surface

prolonged the release. The cumulative urea released from the capsule with a 1 layer coating,

produced after 5, 10, 30 and 90 h immersion in aqueous medium, was 25, 72, 80 and 90%,

respectively. It must be noted that with an increase in the NR-g-CPAM coating, the capsule

matrix becomes denser resulting in a decrease in the rate of urea diffusion through the

swollen beads, especially the beads with the third NR-g-CPAM coating. The possible

mechanism for the release of urea from the capsule is displayed in Figure 33. There could be

many methods for the release of urea from the capsule e.g., erosion of the polymer, diffusion

and stress driven. After the beads were immersed in a water medium, the urea fertilizer was

diffused from the beads due to the swelling of the wall of the water barrier.

Figure 32. Relationship between the release rate of the urea fertiliserfertilizer and the release time from

the beads obtained from different coatings.

Search WWH ::

Custom Search