Environmental Engineering Reference

In-Depth Information

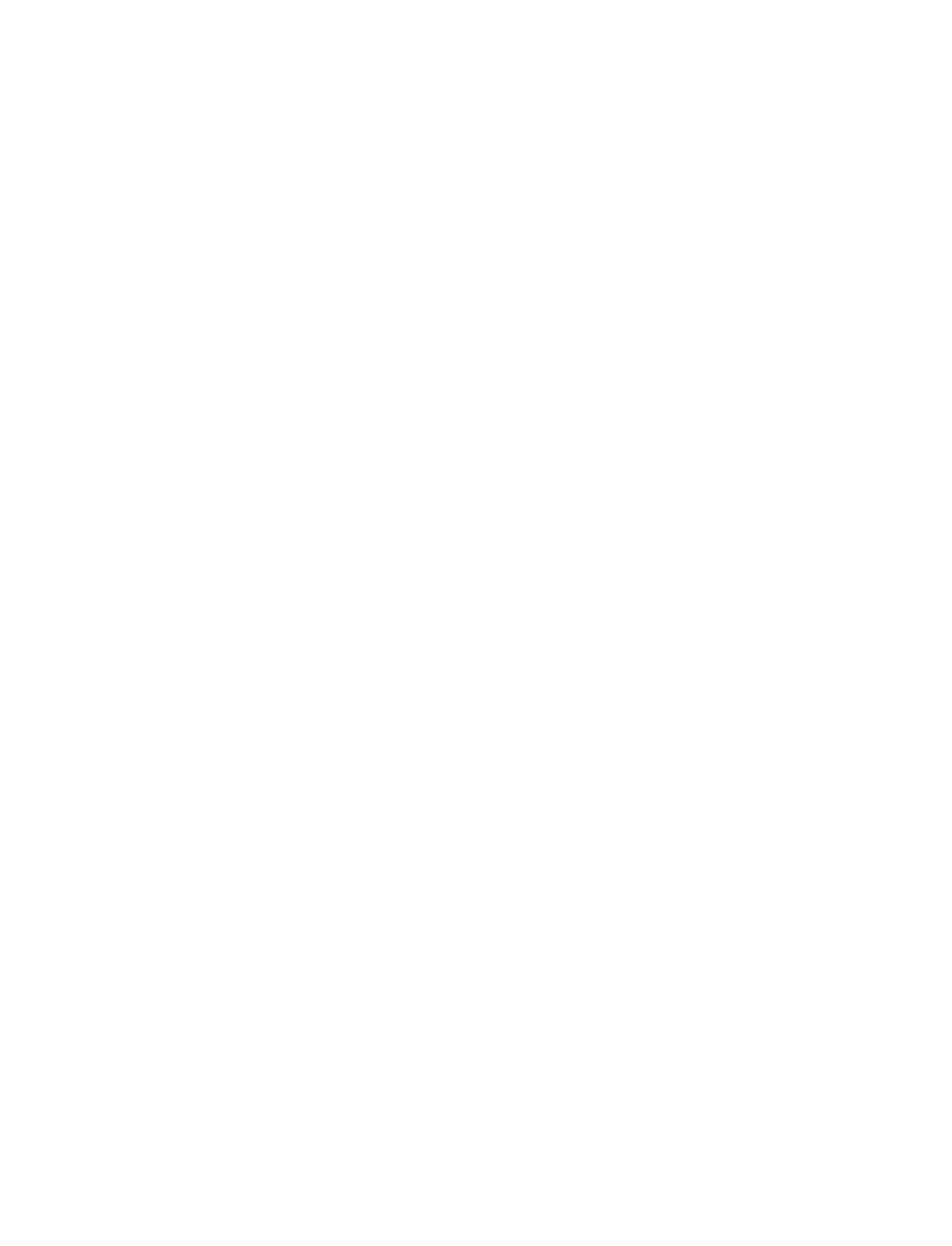

Table 3.8

Potential environmental impacts in the production of 1 kilogram of selected enzymes produced

by Novozymes at the factory gate in Denmark.

Impact category

Units

Termamyl

120 L

Spirizyme

plus FG

Ronozyme

P5000 CT

Savinase

12 TXT

Novamyl

10,000 BG

Global warming

g CO

2

eq.

1,000

7,500

2,000

4,250

10,200

Acidification

g SO

2

eq.

5

24

6

14

29

Nutrient enrichment

g PO

4

eq.

2.0

22

2.5

0.5

7.0

Photochemical

ozone formation

g ethylene eq.

0.6

2.7

0.7

1.2

3.0

Energy consumption

MJ

12

87

35

65

125

Use of agricultural

land

m

2

year

0.4

3.5

0.3

0.4

2.0

Termamyl 120 L

: Bacterial alpha amylase used for liquefaction of starch in the production of high-fructose syrup.

Spirizyme plus FG

: Fungal glucoamylase used for saccharification of starch in the production of starch derived sugars.

Ronozyme P5000 CT

: Fungal phytase used for the release of phytate bound phosphate in the preparation of animal feeds

(pig, poultry, farmed fish).

Savinase 12 TXT

: Bacterial protease used in detergents for the removal of protein stains.

Novamyl 10,000 BG

: Bacterial amylase that diminish the crystallization of starch used as an anti-staling agent in industrial

bread production.

Adapted from Nielsen et al., 2007, and reproduced with permission from Springer.

However, data of Table 3.8 comes from a cradle-to-gate analysis that indicates the impact

per kilogram of enzyme. For a more accurate analysis, the impacts should be based on

enzyme activity instead of weight. However, for enzymes that perform different functions,

as the ones presented in Table 3.8, it is not possible to perform a comparative analysis.

Another important observation about the data presented in Table 3.8 is the high correlation

coefficient between energy consumption and global warming (R

2

= 0.9759) and energy con-

sumption and acidification (R

2

= 0.9488), which indicates that global warming potential and

acidification are most likely caused by the production of energy.

Impact of packaging

The description of the environmental impact of packaging is presented in Chapter 12.

Impact of processing

Food processing is highly diverse in terms of processes and raw materials, and so are the

environmental impacts produced by each type of food industry. Depending on the raw mate-

rial and the degree of processing every food product requires, the magnitude of the impact will

vary at different stages of the supply food chain.

The overall impact of food products varies on a product-to-product basis, and to illustrate

the idea, the potential impact on climate change at five stages of the supply chain will be ana-

lyzed for the following products: tomato ketchup, organic potatoes, medium-fat milk, bread,

and bone-free pig meat. Data for this example were obtained from published papers on life

cycle assessment for these five products in Europe.

Figure 3.7 presents the grams of carbon dioxide equivalent per kilogram of product at the

agriculture stage, processing, packaging, transportation, and consumption. The first observa-

tion is that for both animal products, milk and pig meat, the highest impact occurs at the agri-

cultural stage with 84 and 88 percent respectively. At the opposite end of the spectrum, organic

potatoes show to have the highest impact during transportation and consumption. Cooking

potatoes takes significant amounts of energy with the associated emissions of carbon dioxide.