Environmental Engineering Reference

In-Depth Information

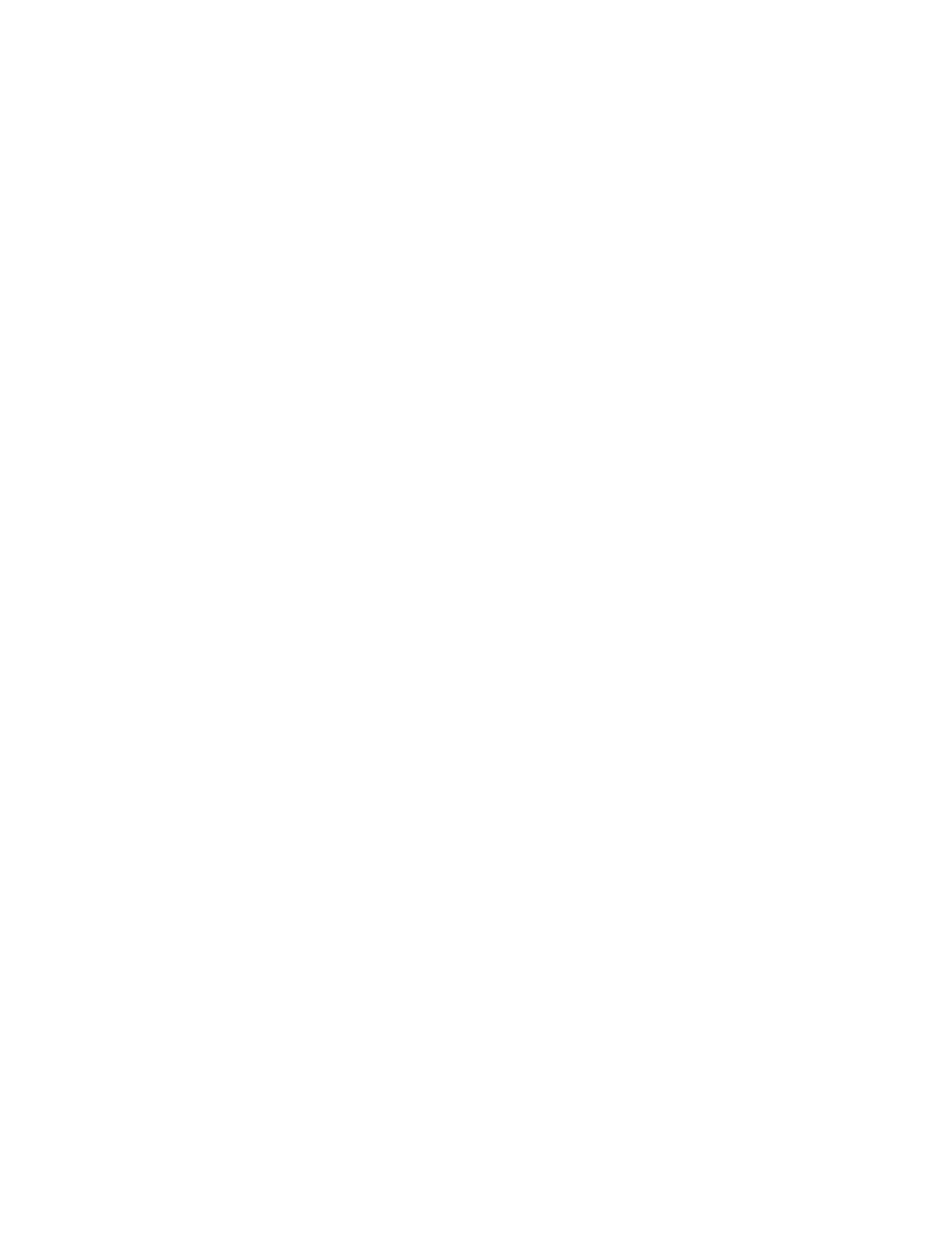

Table 12.2

Energy intensity for the manufacture of food packages.

Package

Energy (MJ)

Styrofoam tray (size 6)

0.90

Molded paper tray (size 6)

1.61

Polyethylene pouch (16 oz, or 455 g)

2.34

Steel can, aluminum top (12 oz)

2.38

Steel can, steel top (16 oz)

4.21

Glass jar (16 oz)

4.28

Coca-Cola bottle, nonreturnable (16 oz)

6.16

Aluminum can, pop-top (12 oz)

6.88

Plastic milk container, disposable (1/2 gal)

9.04

Polyethylene bottle (1 qt)

10.44

Polypropylene bottle (1 qt)

11.52

Adapted with permission from Pimentel and Pimentel, 2008.

Steel

Steelmaking is not as energy intensive as aluminum production, but still iron and steel manu-

facturing is the largest energy consumer among all manufacturing industries (Strezov, 2006).

Energy spent per metric ton of steel produced depends on the method and concentration of the

ore (Table 12.3). On average, 24 GJ are spent per metric ton to produce steel on a worldwide

basis. Most energy-efficient processes use 19 GJ/tonne for primary steel and 7 GJ/tonne for

secondary steel manufacturing (de Beer et al., 1998). Parker (1991) reports 27 GJ/tonne, and

the American Iron and Steel Institute (AISI) states that in the United States on average, the

energy intensity for steel production is 14.6 GJ/tonne (12.6 10

6

Btu/short ton), shipped 22.7 GJ/

tonne (19.55 10

6

Btu/ton) for integrated steelmakers, and 6.1 GJ/tonne (5.25 10

6

Btu/ton) for

electric steelmakers (AISI, 2005).

Besides energy spent during steel manufacturing, additional energy is needed to transform

the liquid steel into a strip, and before forming the metal into cans, a protective layer of tin or

other surface coating material needs to be added. Boustead and Hancock (1981) estimate

5.88 MJ/kg (5880 MJ/tonne) is the energy spent to transform liquid steel into a hot rolled slab

that is subsequently formed into a strip.

Tin coating takes place in a separate facility from where the hot rolled strip is produced. It

takes approximately 10 MJ to produce 1-kilogram of tin-coated steel and 8.6 MJ to produce

1-kg of tin-free steel, which is protected by a chrome layer, from a hot rolled coil (Boustead

and Hancock, 1981).

Furthermore, to avoid internal corrosion and contamination of the food product with dis-

solved metal, interior surfaces of cans are coated with an organic coating. There are several

coating types, such as vinyls, varnishes, and lacquers. The energy intensity to produce an alkyd

varnish is 268 MJ/kg and for an epoxy lacquer 376 MJ/kg (Boustead and Hancock, 1981).

With all the factors involved in producing the materials and forming the container, a 16-oz

steel can needs about 4.21 MJ (Pimentel and Pimentel, 2008).

Petroleum-based plastics

Petroleum-based plastics have the dual impact of using nonrenewable energy (in most cases)

plus the use of the feedstock that otherwise would be used as fuel. To make 1-kg of PET, it

takes 37 MJ of energy and the equivalent of 39 MJ of petroleum-derived raw materials totaling

76 MJ/kg (Gerngross and Slater, 2000). Then, turning PET into bottles takes another 20 MJ/kg

per finished bottle (Gleick and Cooley, 2009).