Environmental Engineering Reference

In-Depth Information

Efficiency of CHP systems

In terms of energy output to total fuel consumed, the overall efficiency of a CHP system can

be calculated as follows:

Electrical energy Useful thermal energy

Fuel energy input

+

[11.5]

η

=

CHP

For separate heat and power, the thermal efficiency for the boiler (

h

Boiler

) and the efficiency

for electricity only generation (

h

Electricity

) are as follow:

Useful thermal output

Fuel energy input

[11.6]

η

=

Boiler

Energy output

Fuel energy input

[11.7]

η

=

Electricity

The overall efficiency of separate heat and power is then:

Electrical energy

+

Useful thermal energy

η

=

[11.8]

SHP

Electrical energy

η

+

Useful thermal energy

η

Electricity

Boiler

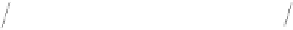

Figure 11.8 presents a comparison between a conventional separate heat and power system

with a CHP. For the purpose of illustration, assume that 30 units of electricity and 45 units

of heat are needed for a particular process and that the efficiency for the boiler is 80 percent

and for the power plant 31 percent. To produce the same amount of electricity and heat,

the conventional generation system needs 154 units of fuel to generate 75 (30 + 45) units of

energy, resulting in an overall efficiency of 49 percent (75/154), or according to Equation

11.6

h

SHP

= [30 + 45]/[30/0.31 + 45/0.8]). On the other side, the CHP system uses only

100 units of energy to produce the same output, so the overall efficiency is 75 percent

(EPA, 2008).

Conventional

generation

Combined heat

and power

Power plant

fuel (98 units)

30 units

electricity

Power plant

Combined

heat and

power

154 units fuel

100 units fuel

Boiler fuel

(56 units)

Heat

Heat

45 units

steam

Boiler

49% overall

efficiency

75% overall

efficiency

Figure 11.8

Conventional generation of electricity and heat and a combined heat and power unit (CHP).

Adapted from Environmental Protection Agency (EPA), 2008.