Environmental Engineering Reference

In-Depth Information

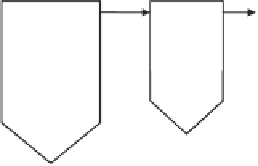

(A)

Biogas

(B)

Biogas

Gas/solids

separator

Effluent

Effluent

Settling

tank

Liquid

Sludge blanket

Feed

Feed

Solids recirculated

Complete mix reactor with sludge

recirculation

Up-flow anaerobic sludge blanket

Biogas

Biogas

(C)

(D)

Effluent

Effluent

Packed bed

Sludge

granule

Feed

Feed

Up-flow packed bed attached growth

Attached growth anaerobic fluidized

bed

Figure 9.7

Most common anaerobic systems for wastewater treatment.

Attached growth anaerobic fluidized bed reactor

This reactor is a variation of the “upflow attached growth anaerobic expanded-bed reactor,”

which is packed with sand with a diameter between 0.2 to 0.5 mm. The velocity of circulation

(about 2 m/h) is adjusted to allow an expansion of the bed of up to 20 percent. In the attached

growth anaerobic fluidized bed reactor, the speed is increased up to one order of magnitude

(20 m/h) to promote the total bed expansion (Fig. 9.7D) (Tchobanoglous et al., 2004).

Advantages of the fluidized bed reactors are high treatment efficiency, no clogging, small

area requirements, high activity, and good separation of gas from liquid. Disadvantages

include long start-up times, difficulty to control thickness of biolayer, high energy consump-

tion for pumping, and high cost of the equipment (Saravanane and Murthy, 2000).

Posttreatment after anaerobic step

In most cases, anaerobic treatment alone is not enough to achieve a degree of purity that would

allow effluent discharge to surface waters, reuse of the water, or groundwater recharge; there-

fore, it needs an additional polishing step. Water leaving the anaerobic reactor may still con-

tain nutrients (e.g., nitrogen and phosphorus), hydrogen sulfide, odors, suspended solids,

pathogens, color substances, and particulate chemical oxygen demand that need to be reduced

to acceptable levels (Tilche et al., 1996).