Environmental Engineering Reference

In-Depth Information

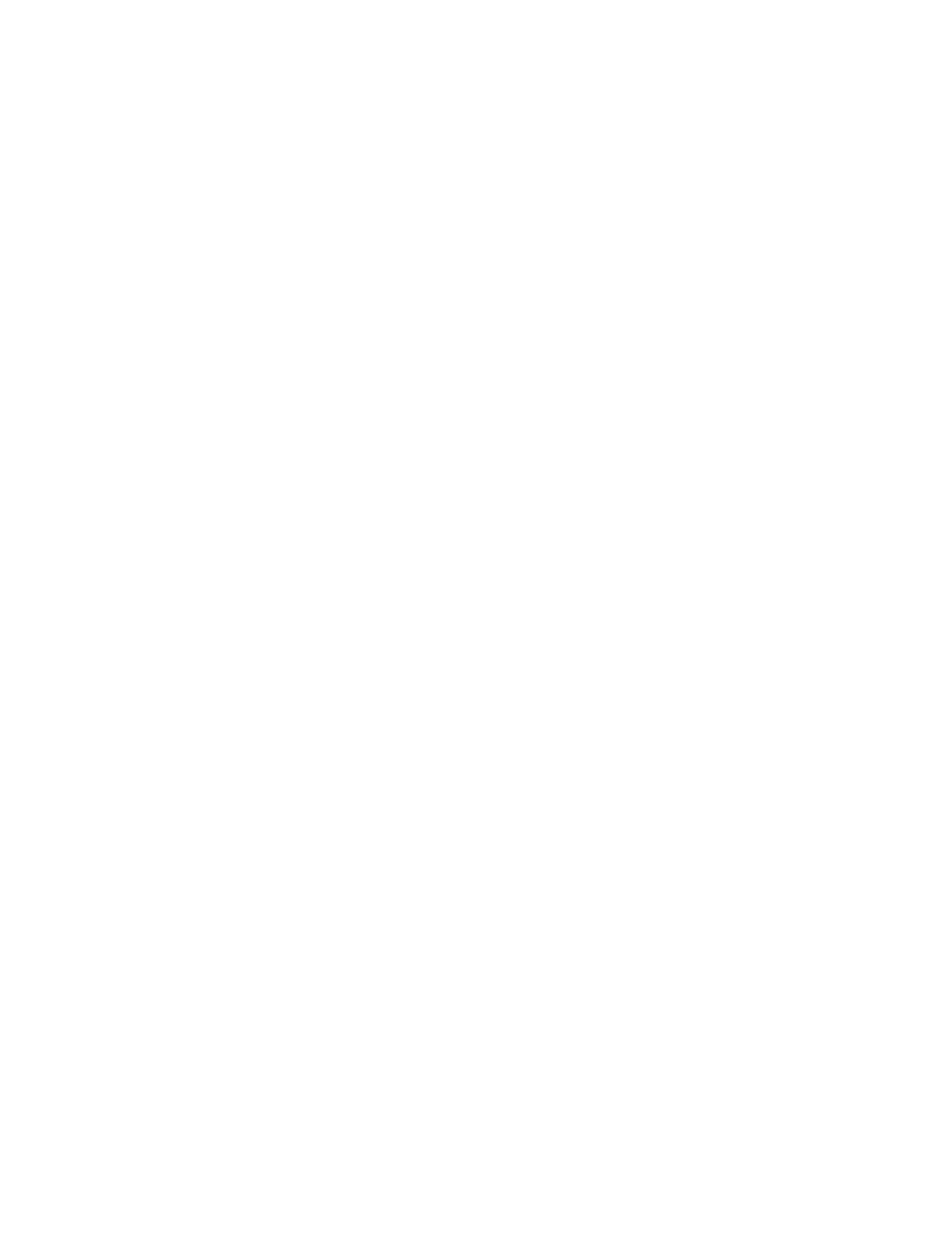

Table 9.6

Virtual water in animal products produced in selected countries (L/kg).

Beef

Pork Goat meat Sheep meat Chicken meat

Eggs

Milk

United States

13,193

3,946

3,082

5,977

2,389

1,510

695

China

12,560

2,211

3,994

5,202

3,652

3,550

1.000

India

16,482

4,397

5,187

6,692

7,736

7,531

1.369

Russia

21,028

6,947

5,290

7,621

5,763

4,919

1.345

Indonesia

14,818

3,938

4,543

5,956

5,549

5,400

1.143

Australia

17,112

5,909

3,839

6,947

2,914

1,844

915

Brazil

16,961

4,818

4,175

6,267

3,913

3,337

1.001

Japan

11,019

4,962

2,560

3,571

2,977

1,884

812

Mexico

37,762

6,559

10,252

16,878

5,013

4,277

2.382

Italy

21,167

6,377

4,180

7,572

2,198

1,389

861

Netherlands

11,681

3,790

2,791

5,298

2,222

1404

641

World average

15,497

4,856

4,043

6,143

3,918

3,340

990

Reproduced from Hoekstra and Chapagain, 2007, with permission of Springer.

watersheds or supporting communities with no access to clean water. Other ways of working

toward water neutrality are reducing water extraction from aquifers and surface water by har-

vesting rainwater or by treating and reusing grey water.

The concept of water neutrality can be a good initiative as far as it is not misrepresented as

being the equivalent to “zero net use,” which would be an oxymoron in the food industry,

especially in the beverages sector where water is the main ingredient. Caution should be exer-

cised either when making claims or responding to claims about water neutrality because it is

a concept that, if taken out context, can easily be cited as “greenwash.”

EFFICIENCY OF WATER USE IN FOOD PROCESSING

Water used in processing plants produce impacts at local, regional, and global levels due

to its uptake from local resources (e.g., aquifers), the potabilization process, which

requires energy and chemicals, and the generation of effluents. In most cases, effluents

coming out of processing plants has high solid contents and needs treatment before it is

returned to water bodies. Wastewater treatment uses energy and chemicals and cause a

direct impact by the direct release of GHGs, such as carbon dioxide and methane. So,

improving the efficiency of water consumption not only contributes to the preservation of

this valuable resource but also saves money and reduces direct and indirect carbon

emissions.

Water consumption in processed foods, such as canned products, is high, especially in

the fruits and vegetables industry. The fruit canning industry in the United States produces an

average volume of wastewater of 13,425 gallons/ton for pineapples, 31,875 gallons/ton for

cherries, 16,145 gallons/ton for peaches, and 27,685 gallons/ton for apples (North Carolina

Department of Environment and Natural Resources [NCDENR], 2009). In addition, the use of

water in the food industry is far from optimized, and there is a broad variability in water use

by industries that process the same product. Figure 9.6 shows the raw wastewater volume

(which is directly correlated with the water used) produced by plants that process fruits and

vegetables in the United States.