Agriculture Reference

In-Depth Information

QUALITY

CONTROL

QUALITY

CONTROL

Centrifugation

−

80

°

C

Amplification

Strains library

Fermentation

QUALITY

CONTROL

H

2

O

H

2

O

Blending

Freeze drying

Packaging

Grinding

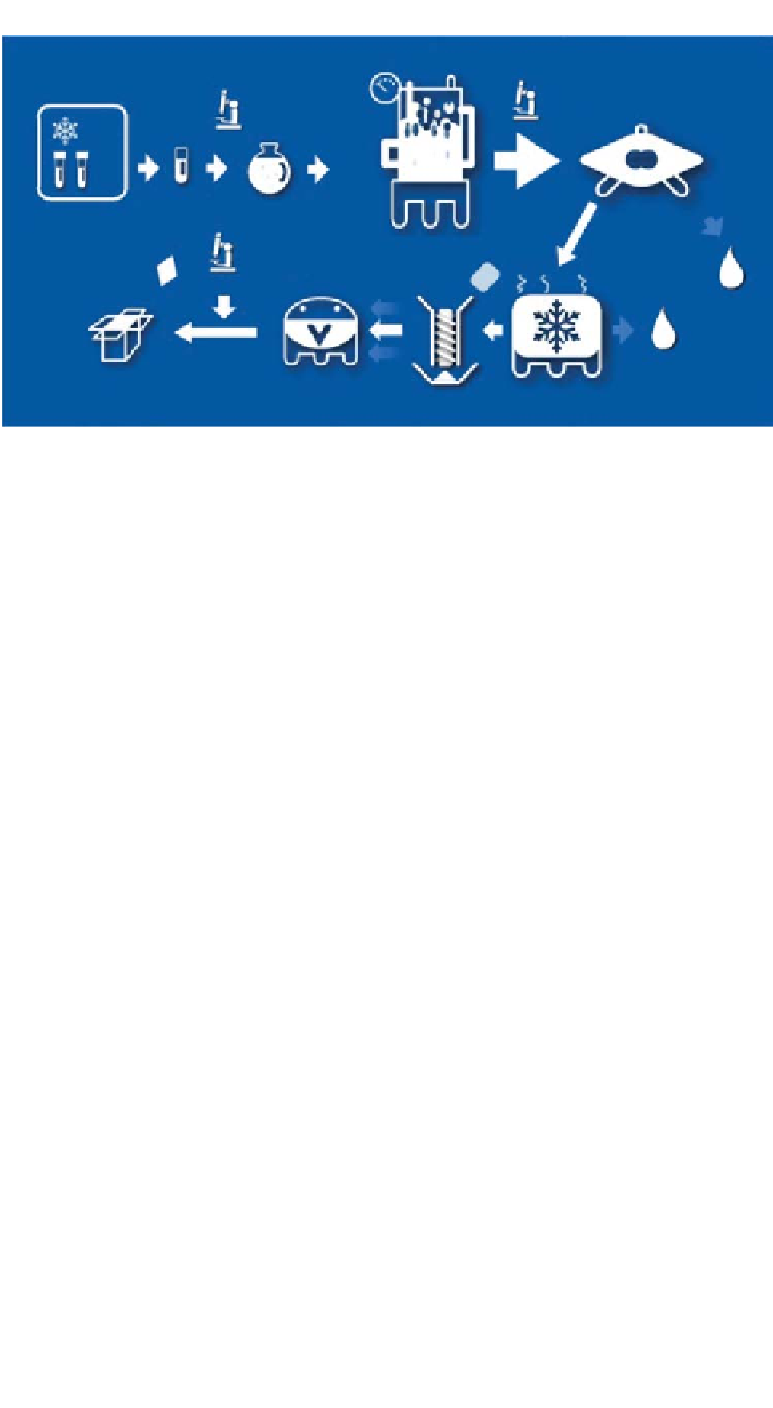

Fig. 13.1

Schematic representation of a probiotic bacteria production process. For colour detail

see Plate 17.

One key element to ensure that the strain being grown is strictly identical to the one selected

is to ensure consistency with the stock culture. The pure strains, when selected for probiotic

use, should be deposited in recognized culture collections which may as part of the contract

maintain the pure culture inoculums from which subcultures for industrial scale-up could be

produced. It is essential to undertake regular genetic profiling to ensure the purity of the strain,

comparing the genetic identity against the deposited strain. As discussed by Wang

etal

. (2008),

producers of probiotics for aquaculture use should also consider quick modern molecular tech-

niques to test and ensure the identity of their strains for both quality and safety assurance.

Probiotic production involves unique and complex processes, which require substantial and

continuous research and development to fine-tune the fermentation process, the further down-

stream processing, and the ultimate packaging in terms of conditions and materials. Such

parameters should be adapted with regards to the strains concerned. It is also essential that

the producer has total control over all of the aspects previously mentioned in order to continue

to ensure the safety, composition, purity, stability and quality of the product as well as the trace-

ability and most importantly the efficacy. Some of the pertinent steps that must be considered

in producing high quality probiotics, for example bacteria, are illustrated in Figure 13.1.

The process starts with a few microlitres of the probiotic suspension (from cell bank vials)

grown in successive scale-ups to eventually larger scale industrial fermentors. This typically

starts with the inoculum introduced in a flask containing the appropriate culture medium,

under sterile conditions. At their optimal preferred growth conditions, the microorganisms

multiply and each batch is successively aseptically transferred to larger containers. The qual-

ity and purity of the culture are checked at each stage and the conditions (pH, temperature,

pressure etc.) are continuously monitored to ensure optimal growth. Microorganisms have

typical growth patterns, but these usually include a lag phase (where the organism is probably

adjusting to the growth conditions) then an exponential phase (multiplication) followed by a

plateau (the stationary phase) after which there is the death phase. The conditions for optimal

Search WWH ::

Custom Search