Environmental Engineering Reference

In-Depth Information

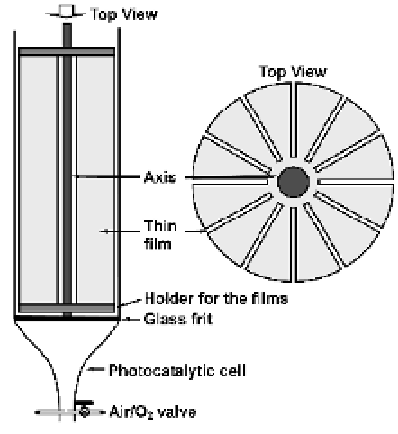

specific surface to volume ratio; (b) improved light transparence; (c) increased degree of

mixing; (d) flexible design operation, which can be installed in other tube reactors, such

as a plug flow reactor and a CPC system; and (e) thin film coating, which allows

possible electron reclamation and energy recovery. It has been reported that the

treatment efficiency is proportional to the slides' number. When 12-slide configuration

is used, the reaction rate is only 1.8 times less than the slurry reactor, which is a very

promising result (Cernigoj et al., 2007).

Figure 3.10.

Schematic representation of a Carberry type reactor (Redrawn from

Cernigoj et al., 2007).

3.4.1.4 Photoelectrochemical Cell (PEC) Reactor

In order to reclaim and maximize the electrons generated during the

photocatalytic process, various attempts have been developed. The PEC system is one

of them (Pecchi et al., 2001). The direction of electron flow in a TiO

2

/liquid junction

PEC system is manipulated by the relative energy position between the semiconductor

bandedges (E

C

and E

V

) and the Fermi energy of the redox couple species (E

F

o

redox

)

at the

solid/liquid interface. To warren an efficient photoactivity, one has to maintain a large

reduction potential (φ

O

) of the acceptor redox couples and an oxidation potential (φ

R

) of

the donor redox couples. The PEC system, which consists of a photoelectrode, reference

electrode and counter electrode, is capable of maneuvering the φ

O

and

φ

R

(Figure 3.11).

In a PEC system, the separation of the photoanode and the cathode is analogous

to the isolation of E

V

and E

C

in the semiconductor. The PEC system provides a high-

Search WWH ::

Custom Search