Environmental Engineering Reference

In-Depth Information

doping level, system design and operation variables also contribute to the overall

photocatalytic performance. The following section addresses some of the pertinent

reaction variables, such as reactor design, light intensity and solution chemistry.

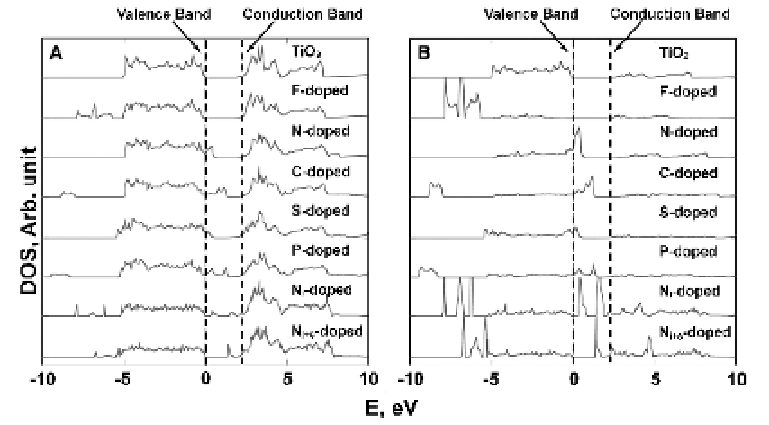

Figure 3.7

(A) Total DOSs of doped TiO

2

and (B) the projected DOSs into the doped

anion sites (Modified from Asahi et al., 2001).

3.4.1 Photocatalytic Reactors

3.4.1.1 Slurry Reaction System

A variety of photocatalytic reactors have been developed in photocatalytic water

purification studies and applications. In most laboratory photocatalytic studies, well-

mixed heterogeneous slurry batch reactors have been employed, due to their simple

configuration and high efficiency. Figure 3.8 gives a schematic illustration of a typical

batch slurry reactor configuration (Lizama et al., 2002). Slurry of fine TiO

2

suspension

is dispersed in the aqueous phase by agitation with irradiation coming from either

outside or the center of the reactor. Aeration of air bubble, pure O

2

or O

3

is commonly

used to maintain a constant electron acceptor level for preventing recombination

ofelectrons and holes on the TiO

2

surfaces, and to provide homogenous dispersion of the

fine catalyst particles.

The limitations of slurry reactors are obvious. Due to the opacity of the slurry,

the light intensity may vary significantly throughout the reactor, which can reduce the

photoreaction efficiency. Moreover, after the photocatalytic oxidation process, post-

Search WWH ::

Custom Search