Environmental Engineering Reference

In-Depth Information

(Eq. 15.16)

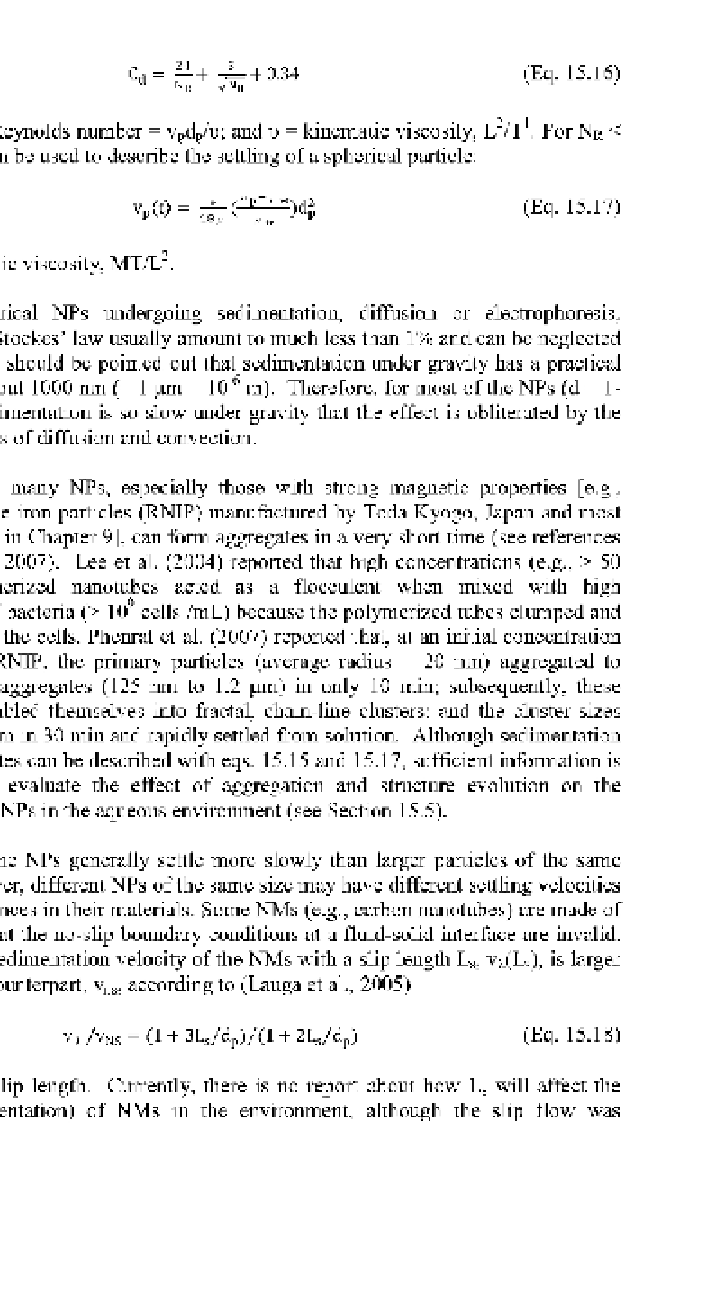

where NR = the Reynolds number = v

p

d

p

/D; and D = kinematic viscosity, L /T . For NR <

L /

1, Stokes' law can be used to describe the settling of a spherical particle:

v

pW=^(^T)

d

P

(Eq. 15.17)

where |i = dynamic viscosity, MT/L .

For spherical NPs undergoing sedimentation, diffusion or electrophoresis,

deviations from Stockes' law usually amount to much less than 1% and can be neglected

(Shaw, 1992). It should be pointed out that sedimentation under gravity has a practical

lower limit of about 1000 nm (= 1 urn = 10"

6

m). Therefore, for most of the NPs (d = 1-

100 nm), the sedimentation is so slow under gravity that the effect is obliterated by the

mixing tendencies of diffusion and convection.

However, many NPs, especially those with strong magnetic properties [e.g.,

reactive nanoscale iron particles (RNIP) manufactured by Toda Kyogo, Japan and most

of NPs described in Chapter 9], can form aggregates in a very short time (see references

in Phenrat et al., 2007). Lee et al. (2004) reported that high concentrations (e.g., > 50

ug/L) of polymerized nanotubes acted as a flocculent when mixed with high

concentrations of bacteria (> 10 cells /mL) because the polymerized tubes clumped and

precipitated with the cells. Phenrat et al. (2007) reported that, at an initial concentration

of 60 mg/L of RNIP, the primary particles (average radius = 20 nm) aggregated to

micrometer- size aggregates (125 nm to 1.2 um) in only 10 min; subsequently, these

aggregates assembled themselves into fractal, chain-line clusters; and the cluster sizes

reached 20 -70 urn in 30 min and rapidly settled from solution. Although sedimentation

of NMs' aggregates can be described with eqs. 15.15 and 15.17, sufficient information is

not available to evaluate the effect of aggregation and structure evolution on the

sedimentation of NPs in the aqueous environment (see Section 15.5).

Waterborne NPs generally settle more slowly than larger particles of the same

materials. However, different NPs of the same size may have different settling velocities

due to the differences in their materials. Some NMs (e.g., carbon nanotubes) are made of

materials such that the no-slip boundary conditions at a fluid-solid interface are invalid.

As a result, the sedimentation velocity of the NMs with a slip length L

s

, v^(L

s

), is larger

than its no-slip counterpart, v

ns

, according to (Lauga et al., 2005)

VI/VNS = (1 + 3L

s

/d

p

)/(l + 2L

s

/d

p

)

(Eq. 15.18)

where L

s

= the slip length. Currently, there is no report about how L

s

will affect the

transport (sedimentation) of NMs in the environment, although the slip flow was

Search WWH ::

Custom Search