Environmental Engineering Reference

In-Depth Information

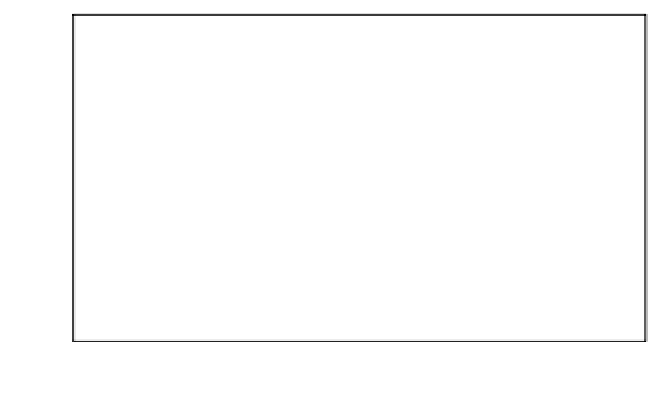

100

90

80

70

60

50

40

30

Cu(II)

Ni(II)

20

10

0

0.001M

0.01M

0.05M

0.1M

0.2M

HCl Concentration

Figure 9.25

Desorption efficiency of adsorbed Cu(II)/Ni(II) by HCl of 0.0010.2M.

9.5.2.7 Desorption Kinetics

For desorption kinetic studies, 40 mL of 0.01 M NaOH and 40 mL of 0.05 M

HCl were used for the desorption of adsorbed Cr and Cu/Ni, respectively. The effect of

contact time on the desorption of Cr(VI), Cu(II) and Ni(II) is shown in Figure 9.26. The

rate of metal desorption decreased gradually till constant after 60 minutes. The

desorption equilibrium time of these three metals was found to be 30 minutes with

defining the value of c/t to be lower than 0.01.

9.5.2.8 Regeneration Studies

Regeneration of adsorbents is commonly accomplished with heat, chemical

change or solvent action. The use of the adsorption system for product recovery is

generally a well understood principle, but not widely practiced due to the technical

limitations. Successive adsorption-desorption processes were carried out within five

cycles. As aforementioned, the first 5 mL of NaOH only can remove 90% of the

adsorbed Cr(VI) from -Fe

2

O

3

nanoparticles, and therefore, some active sites were still

occupied by chromium, resulting in less sites for the next cycle of Cr(VI) adsorption. To

improve the complete desorption of adsorbed Cr(VI), the -Fe

2

O

3

nanoparticles were

separated and then added into another 2 mL of 0.01 M NaOH and shaken for 30 minutes.

Subsequently, the nanoparticles were thoroughly washed with ultrapure water and

Search WWH ::

Custom Search