Environmental Engineering Reference

In-Depth Information

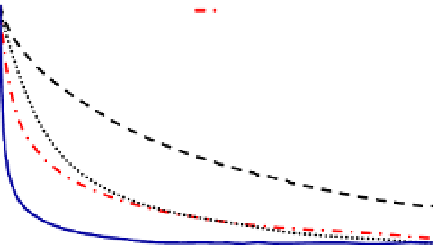

1.0

B(62/36/2)

D(67/29/4)

C(72.5/21/6.8)

Bare nZVI

0.8

0.6

0.4

0.2

0.0

0

20

40

60

80

100

120

Time (min)

Figure 8.6

Results from nZVI sedimentation studies. B, C and D are samples of

polymer with different weight percents of polydimethylsiloxane (PDMS), polyethylene

glycol (PEG) and acrylic acid (AA). For example, polymer B (62/36/2) contains 62%

PDMS, 36% PEG and 2% AA.

To test the versatility of the APGCs in improving the dispersibility of

nanoparticles, silver nanoparticles (AgNP, 100nm, Aldrich) were also coated, and

sedimentation studies carried out. The results indicated that there is no change in

colloidal properties of AgNP when coated with the APGC. The sedimentation plot for

the coated AgNP was essentially the same as that of the bare particles (Figure 8.7). Ag

(molecular weight ~108 g mol

-1

) is almost two times heavier than Fe (molecular weight

~56 g mol

-1

), which may be one of the reasons why the AgNP sedimented out so fast.

Change in the APGC architecture might have enhanced the colloidal stability of the

particles but that was beyond the scope of the present research.

The surface coating on the nZVI was achieved by combining nZVI with APGC

and rotating them in a custom made end-over-end shaker for 72 h. The mixing allowed

the nanoparticles to disperse and the polymer to absorb onto the surface of the

nanoparticles. The mixing time of 72 h appeared a little long, and efforts were made to

shorten the mixing time. A 48-h mixing time gave similar results (Figure 8.8). The

authors infer that there is a possibility of shortening the mixing time and, thus, reduce

production cost of the coated nZVI. Further work is needed to optimize the mixing time.

Search WWH ::

Custom Search