Environmental Engineering Reference

In-Depth Information

reaction. The surface reaction usually involves several steps in the overall reaction

including the diffusion of a reactant to the surface, a chemical reaction on the surface,

and the diffusion of a product back into the solution. The rate-limiting step (i.e., the

slowest reaction step requiring the greatest activation energy) determines the overall

kinetics of a reaction. In general, a typical minimum value of the activation energy for

chemical-controlled reactions is ~29 kJ/mol (Brezonik, 1994). Activation energies of the

dechlorination reactions with bimetallic Pd/Fe nanoparticles and iron nanoparticles are

estimated to be 31.1 and 44.9 kJ/mol, respectively (Lien and Zhang, 2007). The decrease

of the activation energy indicated that the dechlorination by bimetallic Pd/Fe

nanoparticles is a catalytic reaction. Palladium on the iron surface serves as a catalyst.

Furthermore, the value of the activation energy also indicates that the surface-chemical

reaction rather than diffusion is the rate-limiting step for metal-mediated dechlorination.

Similar conclusion for the dechlorination of trichloroethylene and carbon tetrachloride

using ZVI was also proposed by Su and Puls (1999) and Scherer et al. (1997),

respectively.

0.3

0.3

0.2

0.2

0.1

0.1

0

0

Engineered bimetallic

Cu/Fe nanoparticles

Engineered bimetallic

Cu/Fe nanoparticles

In situ formed bimetallic

Cu/Fe nanoparticles

In situ formed bimetallic

Cu/Fe nanoparticles

Iron nanoparticles

Iron nanoparticles

$V'F

$V'F

$V

$V

'F

'F

Metal Type

Metal Type

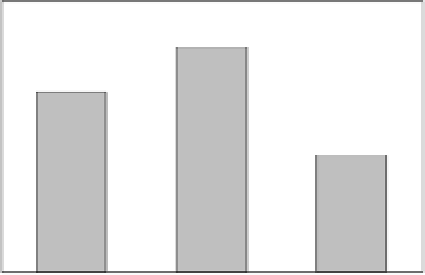

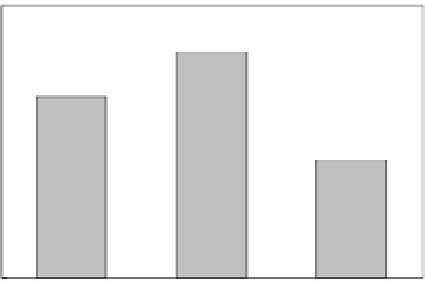

Figure 7.14

Comparison of engineering and in situ formed bimetallic Cu/Fe

nanoparticles for the degradation of carbon tetrachloride.

Reductive dechlorination at metal surfaces involved either direct or indirect

reduction or both (Brewster, 1954; Li and Farrell, 2000). Direct reduction, such as

hydrogenolysis and -elimination in the transformation of trichloroethylene by iron, may

occur via formation of an organic chemisorption complex at the metal surface where

metal itself serves as a direct electron donor. Indirect reduction involves atomic

hydrogen and no direct electron transfer from metals to reactants occurring. Atomic

hydrogen is a very powerful reducing agent that reductively dechlorinates contaminants

Search WWH ::

Custom Search