Environmental Engineering Reference

In-Depth Information

The overall E

o

for this reaction is +0.78 V at 25

o

C, indicating a strongly favorable

reaction from a thermodynamics perspective. The formation of Cu

2

O could be attributed

to the reaction between Fe(II) and Cu(II) in the aqueous solution (Maithreepala and

Doong, 2004):

2

+

2

+

+

(Eq. 7.14)

2Fe

+

2Cu

+

7H

O

→

Cu

O

+

2Fe(OH)

+

8H

2

2

3

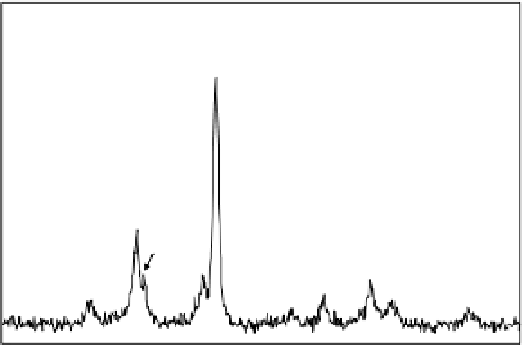

600

Fe

500

400

300

M

200

Cu

2

O

Cu

M

M

M

Fe

Cu

2

O

100

M

0

20

30

40

50

60

70

80

2

θ

Figure 7.12

XRD pattern of Cu(II)-treated iron nanoparticles. M represents magnetite

and/or maghemite.

As iron nanoparticles have the capability of the sequestration of heavy metals,

Table 7.5 summarizes the removal of selected metallic ions by iron nanoparticles. It can

be found that for metals with the standard reduction potential much more positive than

iron such as Cu(II), Ag(I), and Hg(II), the removal mechanism is mainly chemical

reduction (Li and Zhang, 2007). Metals with the standard reduction potential slightly

more positive than iron such as Ni(II) and Pb(II) can be immobilized at the surface of

iron nanoparticles by both adsorption and chemical reduction (Li and Zhang, 2007).

Clearly, this result indicates that in situ formation of bimetallic iron nanoparticles in the

site contaminated with these metallic ions is feasible.

Search WWH ::

Custom Search