Civil Engineering Reference

In-Depth Information

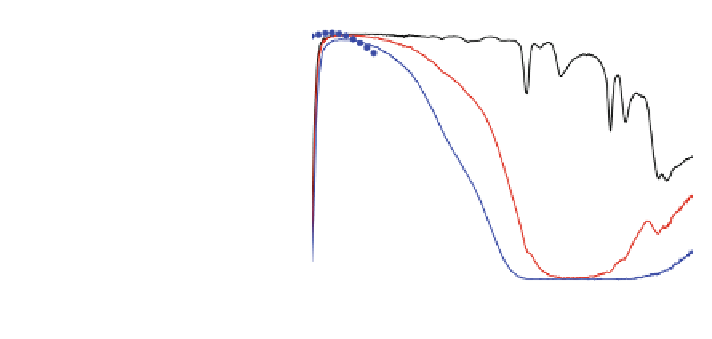

Fig. 13 Spectral

transmittance for

ITO-containing

(PEI-SiO

2

):(LiTFSI)

electrolytes as measured

(curves) and calculated

(symbols). From Bayrak

Pehlivan et al. (

2012b

)

100

80

60

0wt% exp

1wt% exp

1wt% calc

3wt% exp

3wt% calc

5wt% exp

5wt% calc

7wt% exp

7wt% calc

40

20

0

500

1000

1500

2000

2500

Wavelength (nm)

transmittance minimum develops in the near infrared when the ITO content is

increased, whereas the luminous transmittance is almost unchanged (Bayrak

Pehlivan et al.

2012b

). For 7 wt % of ITO, one finds T

lum

= 83.3 % and

T

sol

= 56.3 %, while the electrolyte remains practically free from haze. The

experimental properties can be understood in considerable detail from calcula-

tions, which is a consequence of the accurate theoretical model that exists for

heavily doped wide band-gap oxides such as ITO and its Zn- and Sn-based

alternatives. We note, in passing, that thermochromic VO

2

-based nanoparticles

would be able to transmit more energy at low temperature than at high temperature

(Li et al.

2010

,

2011

,

2012a

), which in principle could lead to additional control of

the solar energy throughput of an electrochromic glazing; these possibilities have

not yet been explored in detail, though.

3 Electrochromic Devices

3.1 Several Challenges

The technology underlying electrochromic glazings involves several steps, and

some of these lie outside the mainstream of today's industrial practice. Clearly, all

these steps must be mastered for successful devices, and failing on one means

failing on the end result. A list of six ''critical'' procedures has been given by

Granqvist (

2008a

) as follows:

Firstly, the electrochromic and counter-electrode films shown in Fig.

2

must be

nanoporous and uniform over large surfaces. There are several ways to accomplish

this, as touched upon in

Sects. 2.1

,

2.2

and discussed in more detail elsewhere

(Granqvist

2012b

,

2013c

). Reactive DC magnetron sputtering at pressures higher

than those typical for metallization may be a preferred technique (cf. Fig.

8

)

(Granqvist

2008b

).