Civil Engineering Reference

In-Depth Information

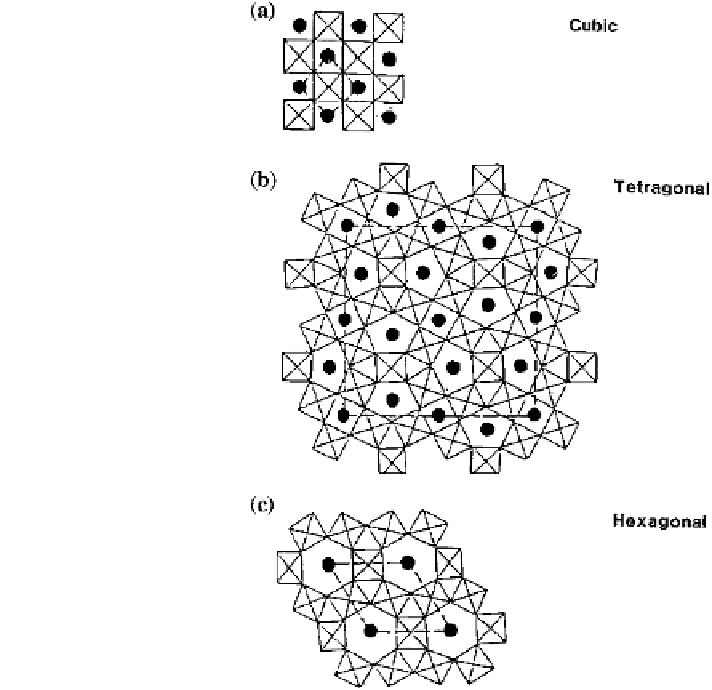

Fig. 6 Structures

representing W oxide with

the shown structures. Dots

indicate sites for ion insertion

in open spaces between WO

6

octahedra. Dashed lines

signify extents of the unit

cells. From Granqvist (

1995

)

spaces between the octahedral units are larger than for the cubic structure, as

indicated in Fig.

6

b. Hexagonal structures, which are delineated in Fig.

6

c, seem

to be formed easily in thin films (Granqvist

1995

), and then, the structure is even

better for ion transport.

The actual nanostructures in thin films of W oxide have been studied several

times, and Fig.

7

reports data based on modeling of X-ray scattering from samples

made by evaporation onto substrates at different temperatures (Nanba and Yasui

1989

). A cluster-type structure is apparent with hexagonal-like units that grow and

interconnect at sufficiently high substrate temperatures.

The relationship between nanostructure and thin-film deposition parameters can

often be well illustrated through ''zone diagrams,'' which have been reported for

different deposition techniques and with different degrees of detail. Figure

8

shows

a ''Thornton diagram'' for the particular case of sputter deposition (Thornton

1974

); more elaborate versions can be found elsewhere (Barna and Adamik

1998

;

Anders

2010

). It is evident that low substrate temperatures and high pressures in

the discharge plasma for the sputtering lead to nanoporous structures of a kind that