Civil Engineering Reference

In-Depth Information

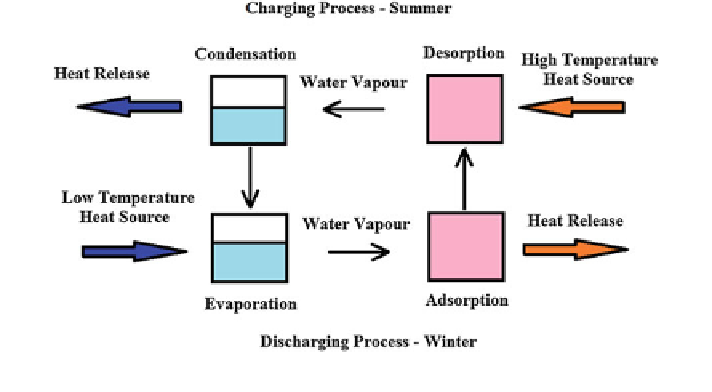

Fig. 9

Operation principle of closed adsorption system

In the discharging cycle, based on the energy demand and the thermal load

conditions prevailing in the evaporator, the stored water is evaporated, and the

vapour is then mixed with the dry silicagel (adsorbent) in the adsorber store. By

this, the silicagel captures the water vapour through adsorption phenomenon and

eventually releases back the stored useful heat energy. Roughly, the storage

density of this system was accounted to be 150 kWh/m

3

of silicagel.

4.9.2 Open Adsorption Energy Storage System

The open adsorption energy storage system also offers an attractive way for storing

and releasing the heat energy upon energy demand requirements in buildings. The

Institute of Thermodynamics and Thermal Engineering (ITW) in the University of

Stuttgart (Germany) has proposed an open adsorption storage named as ITW

Monosorp (N'Tsoukpoe et al.

2009

). This system also utilizes the high-grade solar

energy as the prime heat source for desorption process to take place in the adsorber

store.

In principle, during the regeneration cycle (especially in summer), the solar heat

energy being trapped using the evacuated tube solar collectors and which is

available at a temperature of 180-190 C is fed as the heat input to the incoming

ambient air through a dedicated heat exchange as shown in Fig.

10

.

The heated air is then passed over the zeolite 4A material which is filled inside

the adsorber store. This enables desorption of zeolite 4A to take place by virtue of

vaporizing the water content from the reactive compound. The return warm air is

exhausted to the ambient after preheating the fresh incoming air.

During the discharging period (especially in winter), the wet/moist air from the

indoor spaces is allowed to flow over the adsorbent store, wherein the water