Civil Engineering Reference

In-Depth Information

In building industry, the uses and purposes of fibrous insulation products are

mainly for cavity walls, solid walls, structural insulated panels, roof insulation, and

insulation materials for heating systems as well as water services. Each product

has its own role in different applications depending on its general properties. All

products are likely to have both advantages and disadvantages for use in certain

applications. Therefore, every property required for an application influences

material selection in varying degrees. When choosing a material, consideration

needs to be given such as to the thickness requirement, fire resistance, acoustic

performance, breathability and reliability (BNIM01 2008). Very often, a combi-

nation of different types of product would help to satisfy a wider range of

requirements. Nevertheless, the very first step is to select raw materials. The

selection rules are the same as those applied to the products, according to many

criteria including their thermal, physical, mechanical and chemical properties,

cost, and their human and environmental safety. Obviously, the basic criteria are

the resources of the particular type of raw material, the cost and the manufacturing

progress.

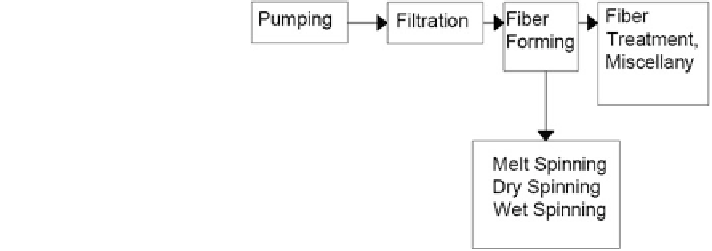

Fundamentals of fibre manufacturing process comprehensively cover the prin-

ciples of transport phenomena and chemical reaction engineering (Weinberger

1996

). Figure

9

summarizes the four main areas of fibre manufacture: pumping,

filtration, fibre forming and fibre treatment, focusing on the fundamentals asso-

ciated with the transport phenomena of fibre production based on the study of

(Weinberger

1996

).

For vegetable fibres, the most commonly used manufacturing process can be

roughly divided into three different steps involving harvesting, fibre processing

and utilization (Dam

1999

), depending on many different factors, such as quality

of the raw materials and quantity of the final product. Figure

10

presents the steps.

Harvest is the process of collecting mature vegetables from the fields which,

basically, involves two processes associated with vegetable fibre: pulling and

reaping. The raw material, flax and hemp for example, is pulled using specific

machines or hands. After pulling, the plants are laid on the filed for drying before

going through retting and extraction process.

The extraction and retting process has a major impact on the fibre product

quality. Vegetable fibres can be extracted manually or mechanically by machines

Fig. 9

Synthetic fibre

module