Civil Engineering Reference

In-Depth Information

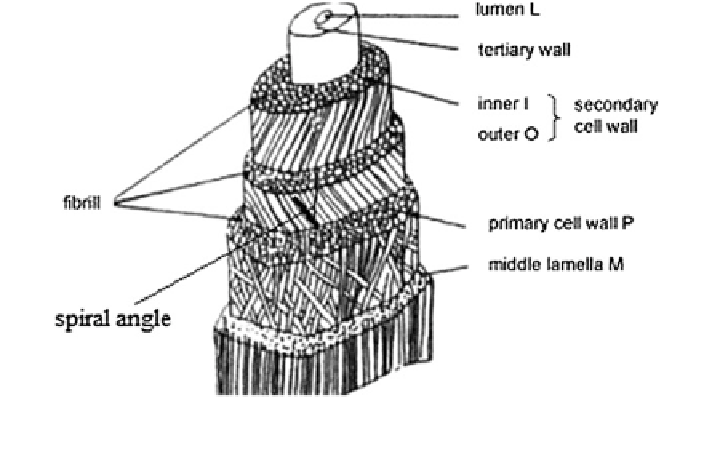

Fig. 5 Schematic structure of a fibre; adapted from (Dufresne

2008

; Rong et al.

2001

; Pietak

et al.

2007

) with kind permission of Elsevier, 2013

properties. Understanding the effects of hierarchical structure can guide the syn-

thesis of fibre-reinforced materials with properties which are tailored for specific

applications. Figure

5

shows that each fibre is consisted of a primary wall, a

secondary wall, a lumen and middle lamellae. The central region of the fibre is the

hollow lumen which transports water and nutrients to the plant or vegetable. The

cell wall has four layers which perform rigidity functions depending on the way

the cellulose microfibrils are arranged. Each layer has characteristics variations in

morphology and composition (Pietak et al.

2007

). The microfibrils in most natural

fibres orient themselves at an angle to the fibre axis called the microfibril angle,

see the spiral angle in Fig.

5

. A weak correlation between strength and cellulose

content and microfibril or spiral angle is found for different vegetable fibres.

Roughly speaking, fibre strength increases with increasing cellulose content and

decreasing spiral angle with respect to fibre axis (Dufresne

2008

). In nature, the

hierarchical structure is primarily driven by chemistry of specific interchain and

intrachain interactions (NMAB

1994

). In the following subsection, a brief

description of some of the basic and important chemical components for vegetable

fibres is presented.

3.2 Chemical Composition

The chemical composition of vegetable fibres varies greatly from one type of

vegetables and one vegetable to another depending on age, environment, season

and extraction process. The principal constituents are cellucose, hemicellucose and