Information Technology Reference

In-Depth Information

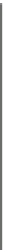

Table 5.1 Classification accuracy for experiments obtained by non-parametric Mixca through

the different levels of the material quality control problem

%

general

Levels of quality of material

Material

condition

96

100

One defect 97

62

Kind of

defect

88.9

100

Hole 82

Crack 88

60

Defect

orientation

X axis

7

2

Y axis

75

XY plane

8

4

ZY plane

9

0

XZ plane

8

9

85.4

100

58

Defect

dimension

P

62

HP

50

P

48

HP

59

P

93

HP

63

P

68

HP

78

P

95

HP

82

78.1

100

54

Abbreviations P passing through, HP half-passing through

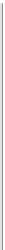

100

95

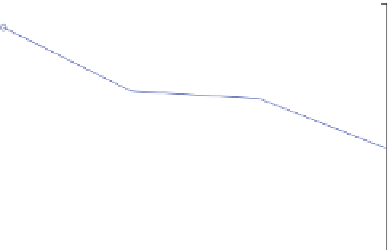

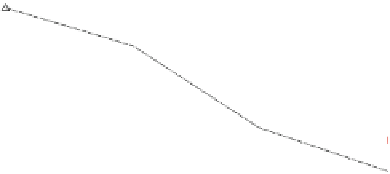

Exp- Mixca-JADE

Exp- Mixca

Exp- MLP

Exp- LDA

Sim- Mixca-JADE

Sim- Mixca

Sim- MLP

Sim- LDA

90

85

80

75

70

65

60

55

Level 1

Level 2

Level 3

Level 4

Classification level

Fig. 5.11 General results of the classifiers in the different levels of classification. Abbreviations:

''Exp'': Experiments, ''Sim'': Simulations, ''Mixca'': non-parametric Mixca

Table

5.2

contains the confusion matrix obtained by non-parametric Mixca in

the defect orientation level. The homogeneous class is perfectly classified, and the

three classes corresponding to cracks are well classified. However, hole classes are

frequently confused with crack classes since the defect geometry does not produce

discernible wave propagation patterns. In addition, the multiple-defect class is

sometimes confused with cracks. This is due to the fact that particular patterns of

one of the defects inside some multiple-defect specimens are more dominant in the

spectra, causing multiple-defect spectra to be similar to crack spectra.

5.4 Conclusions

ICAMM is an extension of ICA that considers a mixture of ICAs. Essentially,

ICAMM is a method for versatile modelling of multivariate data densities that takes

advantage of the statistical independence achieved in every ICA component. Thus,

the very complex problem of modelling statistically-dependent multidimensional

Search WWH ::

Custom Search