Civil Engineering Reference

In-Depth Information

in the chinking. Most locations let you, the owner, wire

your own house, but require that an electrician have a

master's card.

We always drill vertical one-inch holes for the wire

at the doorways, down into the crawl space and up

past switch height, on up through the top plate for

access into the ceiling or roof. For overhead lights, we

often route out a groove in a beam before we floor

upstairs, and drill through for the fixture.

Power companies frown on the practice of embed-

ding wiring in concrete, on the theory that acids will

eat it, or at least the insulation off it. Maybe they're

right; I have no idea what chemicals badger each other

in those combinations. Metal conduit can be used

here, however.

It's obviously easier to properly wire a log house (or

any other house) before it's complete, so I advise you

to go ahead with it. Even the hardiest of my forest-

dwelling cohorts entertains schemes to produce his

own power someday, and even minimal electricity

flows better through adequate circuits.

Do get specific instructions before you wire. It's

expensive to have to do it over. There are numerous

how-to topics on the subject available from the library

or bookstore. And you can take courses in residential

wiring at the local vocational/technical school.

Of course, this could be the ideal place to spend

your dollars on a professional. He'll cost you $40-$60

an hour, however.

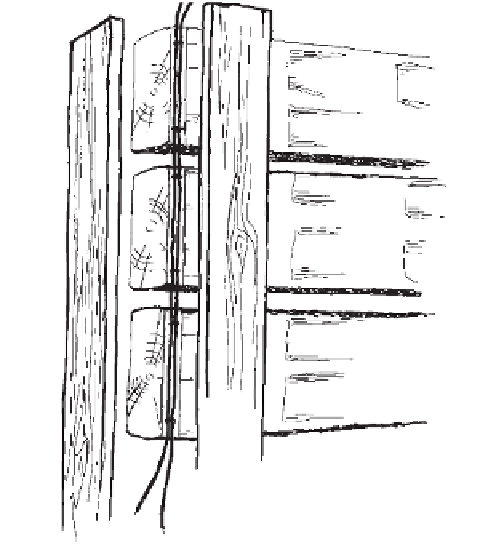

Electric wires can be boxed in under window and door trim (as shown

here) but are better installed in holes drilled through the logs during

assembly. Get specifications from the county inspections office.

Your panel will have a main disconnect switch,

which lets you shut off everything and avoid getting

burned. Every electrician I know has at least once

turned off the wrong breaker switch and discovered it

by burning off the end of his screwdriver on a “dead”

circuit.

Three-wire or two-wire-with-ground, 12-gauge

plastic-covered cable (Romex) is standard for house

wiring. Staple it with the wide, padded staples made

for that purpose. Run circuits wherever possible

between logs.

Vertical wiring goes up best through

drilled logs,

but can be done nicely in a space left by beveling the

log ends, to be covered by facings at windows and

doors. Metal plates must be put over these, so nails

cannot be accidentally driven into the wires later.

Sometimes we bore two intersecting holes through a

log to escape a cul-de-sac at a corner. And with a

raised wood floor, lots of the wire can be strung under-

neath to come up through maybe one log to the out-

lets. The outlets look best mortised into the log faces,

which means drilling from the chinking crack into the

recessed mortises. It's hard to get outlet boxes set flush

Wiring for Telephone

You may miss the telephone the least or the most,

depending on your hang-ups and whether you oper-

ate a business, as we do. Linda could not run her

publications operation or my construction business

without a phone, and wouldn't want to run her life

without one. And now faxes and modems are routine

in even the smallest offices.

Very simply, the telephone company has to be able

to reach you if you want the joys of conventional long-

distance conversations. The company will just about

always come in on an electric company pole, and will

let you bury its line in the same ditch as the electric

cable, at a reasonable 12-inch distance to avoid static.

Or it will bury the line for you at no cost.