Civil Engineering Reference

In-Depth Information

⁄/™"

Underlay shakes with 30-pound felt paper, so that any leaks will run

out on top. Water trapped under the tar paper will rot decking. The

first row of shakes is laid double.

up. Shrinking will split them right where the nails go

in. There are astrological signs best for this activity, as

there seem to be for just about everything else, so if

you're into this sort of thing, lay them up at the

increase of the moon, by all means.

Cedar, cypress, and pine are worked differently.

Square the block first, then go right across the middle

with the froe, one shake at a time. If the block is large,

halve it first. Oak, with its strong radial split lines, will

crack down the middle of the shake if split across the

grain this way, from “shake” cracking.

A word about these woods — second-growth pine

will rot quickly unless treated well with preservative,

which won't last long itself in the rain and sun. Cedar,

of the native red variety, is fine if you trim the white

sapwood off. The western red cedar sold in lumber-

yards is not as durable as the native red cedar. Cypress

is fine, where available. Black walnut would do nicely,

but let's not kid ourselves.

Cedar that can be riven is almost nonexistent today,

except in protected groves, whose owners frown upon

its removal. Even red oak is hard to find, so I've

switched largely to lumber company offerings and

sawn shingles. Even knotty cedar can be sawn nicely.

And oak, if carefully done, can be sawn. I prefer the

cedar, partly for the smell, which I never tire of. Cut

shingles, sliced with a large mechanical knife, can be

bought also, but are quite thin.

In estimating the number of shakes you'll need, fig-

ure the square footage of the roof, including eaves, and

add maybe 200 square feet for waste. Shingles and

shakes are sold by the square or bundle, with a square

being 100 square feet, five bundles to a square. If you

split your own, figure a mountain of blocks, then mul-

tiply that by 10. You still won't have enough.

Lay a double thickness of shakes for the first course

at the bottom, to cover all the cracks. You may want to

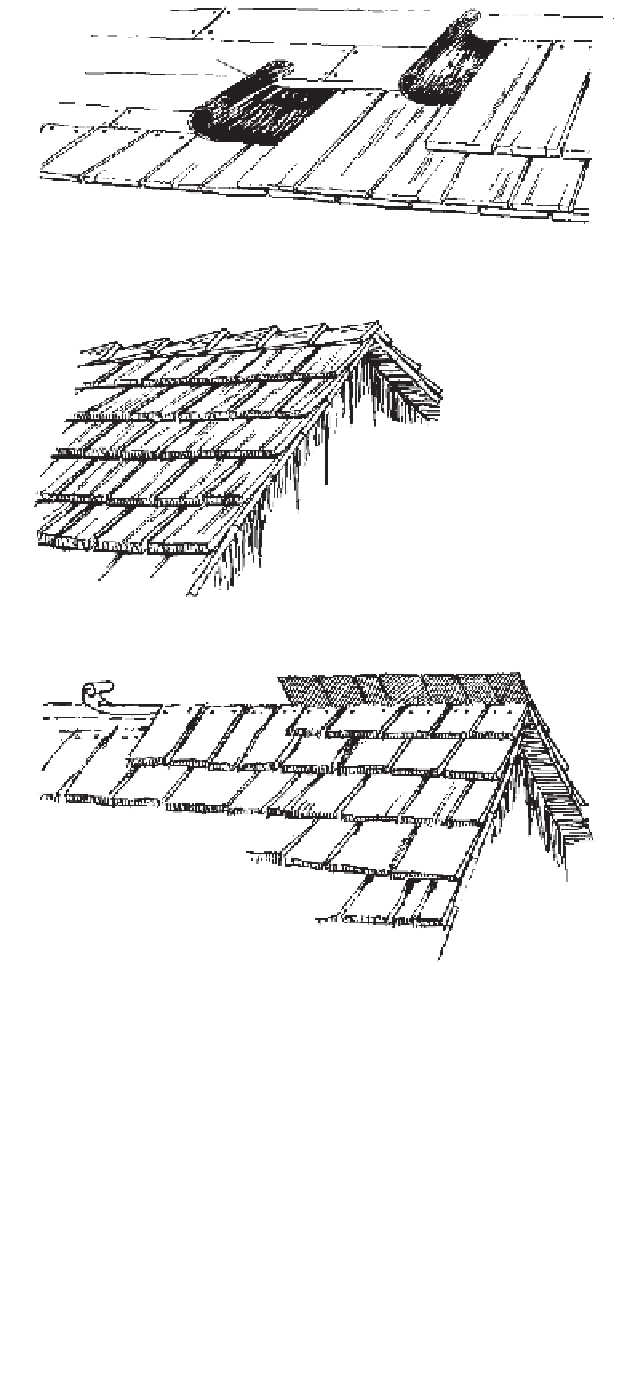

Two peak treatments, both with metal

flashing under. The “turkey feather” is

traditional.

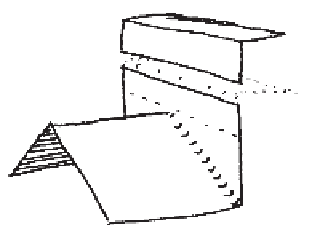

This peak flashing against the chimney should be fabricated so it can

bend in more than one direction. This is a common source of roof leaks

if not done properly.