Agriculture Reference

In-Depth Information

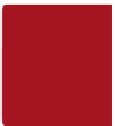

(a)

(b)

Figure 15.5

Hydroponic root media: (a) rockwool modules which are designed to receive the small plants and then at the

appropriate stage the block is moved into or on to rockwool slabs; (b) aggregate clay granules are used to fi ll gullies and

other containers

15

(b)

(a)

Figure 15.6

Hydroponic growing systems: (a) rockwool as polythene-wrapped slabs; (b) perlite in 'bolsters'

water was too difficult to maintain where the quality

of water was poor. It was found that the surplus

nutrient solution was most easily managed by

allowing it to run to waste into the soil. However, this

open system presents environmental problems and

increasingly a closed system has had to be adopted.

It is now becoming more usual to run the waste to a

storage sump via collection gullies or pipes. Some of

this can be used to irrigate outdoor crops if nearby.

To recirculate the water it is necessary to have

equipment to remove the excess fertilizer or accept a

gradual deterioration of the nutrient solution. It is then

flushed out to a sump when it becomes unacceptable.

There was also a risk of a build-up of water-borne

pathogens and trace elements. Sources of infection

such as

Pythium

(see p. 254) are minimized by

isolation from soil and using clean water; the risk of

recirculating pathogens is addressed by sterilizing the

water.

Rockwool is not biodegradable, so the vast quantity

now produced has created a serious disposal problem.

The slabs can be used successfully several times, if

sterilized on each occasion, but eventually they lose

their structure. Tearing them up and incorporating in

composts or soils can deal with a limited amount. Far

more can now be recycled in the production of new

slabs. Increasingly, the mineral aggregate is being

replaced by biodegradable materials processed to

provide a suitable root environment for hydroponics,

such as coir and green waste.

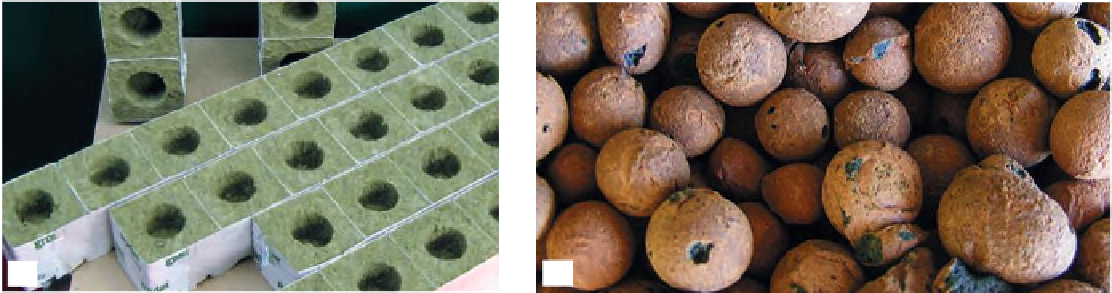

Expanded clay aggregates

such as Leca or Hortag

are made from processed clay which is heated and

then expanded in a rotary kiln. After finishing at a

very high temperature, sterile, tough, lightweight,

honeycombed balls with a smooth surface finish

are created. Granules 4-8 mm in diameter, giving

a

capillary rise

of about 100 mm can be used to

create a good root environment. They are non-toxic,

environmentally inert and are used in hydroponic

growing systems. They have an attractive dry

surface making them useful in decorative containers

(Figure 15.7).