Chemistry Reference

In-Depth Information

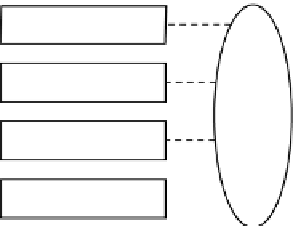

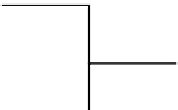

Solvent 1A

Optional Solvent-

Select Valve

Solvent 1B

Pump 1

Outlet

Mixer

Pump 2

Solvent 2A

Optional Solvent-

Select Valve

Solvent 2B

(a)

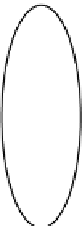

Solvent A

Solvent B

Pump

Head

Outlet

Solvent C

Solvent D

µ-processor

(b)

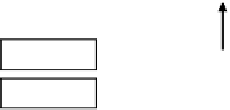

FIgure 3.1

Diagram illustrating (a) high-pressure and (b) low-pressure mixing system

architecture. The high-pressure system uses two separate pumps and a controller; the low-

pressure system uses a single pump and a multiport proportioning valve.

for method and column screening approaches), and the mobile phases are often

more robust and accurate than premixed mobile phases when methods are in rou-

tine use. Figure 3.2 illustrates this capability. Figure 3.2c shows three overlaid chro-

matographic results from one system, three different chemists, on three different

days, using premixed solvents. The chemist-to-chemist reproducibility is seen to be

quite variable. In Figure 3.2b, every tenth injection of 100 runs from an experiment

using premixed solvents are overlaid. Figure 3.2b illustrates that even on a single

system, with a single chemist, premixing solvents can affect repeatability over time.

Variability in this instance most likely arises from selective evaporative loss of the

organic solvent, as later runs have longer retention times. Finally, in Figure 3.2a,

overlaid results are presented for every tenth injection of 100 runs using auto blend

or dial-a-mix; that is, using the system to make the mobile phase. As illustrated, the