Chemistry Reference

In-Depth Information

0.20

0.15

0.10

0.05

0.00

0.00

0.50

1.00

1.50

2.00

2.50

3.00

Minutes

3.50

4.00

4.50

5.00

5.50

6.00

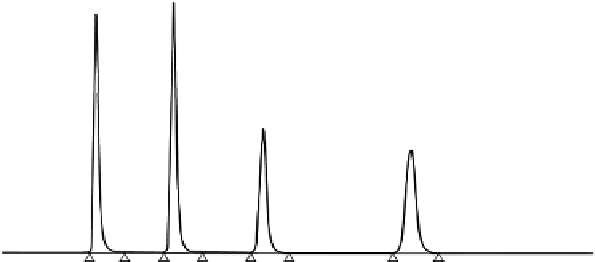

FIgure 2.3

Example of a vendor PQ test. Separation was performed using a 4.6 by 75 mm

3.5-µ Symmetry C18 column (Waters, Milford, Massachusetts) at 30°C. Mobile phase was

40/60 water/methanol v/v at a flow rate of 1.0 mL/min. A 20-µL injection, and UV detection

at 254 nm were used. Peaks are in order: (1) acetone (

t

0

), (2) acetophenone, (3) propiophenone,

and (4) butyrophenone, 0.01 mg/mL each in water.

essence of a holistic OQ and PQ test. Actual user PQ tests should incorporate the

essence of the system suitability section of the general chromatography chapter in

the USP [8] in order to show suitability under conditions of actual use.

2.3.5 P

reventAtIve

m

AIntenAnce

And

r

ePAIrS

As shown in Figure 2.1, after the instrument is placed on-line in the laboratory,

repair (in the case of failure to meet PQ test specifications) or preventative main-

tenance followed by calibration and standardization may be required. While it is

not necessary to requalify an instrument when parts are replaced for minor repairs

or routine maintenance or normal repair, some sort of test to verify the repair or

replacement should to be performed. However, when major repairs are undertaken,

some subset of requalification becomes necessary. Table 2.6 lists typical minor and

major repairs.

Major repair items are ones that have the ability to affect the accuracy, linearity,

or precision of the system or instrument, for example, a pump CPU board. Because

the pump CPU board controls the pump motor drivers that determine proper flow

rates, a CPU board's proper functionality is best determined by performing a com-

plete OQ followed by a system PQ. All major repairs should be documented in the

maintenance log for the module or other suitable log as appropriate.

Minor repair items are items that are unlikely to affect proper operation of the

device, for example, replacing pump seals or detector lamps. Because the problem

can be easily diagnosed and readily verified following repair, it is not necessary to

perform a complete OQ/PQ; performing system suitability analysis (see Chapter 5)

before running any unknowns is usually all that is required. As with any major repair,

minor repairs should also be documented in the maintenance log for the module or

other suitable log as appropriate, along with any testing performed to verify the repair.