Chemistry Reference

In-Depth Information

9.4.1.4 verification process examples

Assessing specificity is often critical to verifying that a compendial procedure is

suitable for use in assaying drug substances and drug products. Specificity for a

chromatographic method may be verified by conformance with system suitability

resolution requirements if they are specified in the method. However, drug sub-

stances from different suppliers may have different impurity profiles that are not

addressed by the compendial test procedure. Similarly, the excipients in a drug

product can vary widely among manufacturers and may have the potential to

directly interfere with the procedure or cause the formation of impurities that are

not addressed by the compendial procedure. In addition, drug products containing

different excipients, antioxidants, buffers, or container extractives may potentially

interfere with the compendial procedure. In these cases, a more thorough assess-

ment of specificity may be required to demonstrate suitability of the method for the

particular drug substance or product, for example, to include photodiode array and

mass spectral analysis.

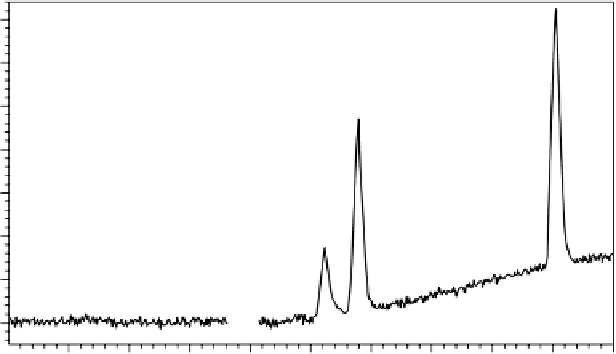

Figure 9.1 shows a separation used to verify a stability indicating compendial

procedure for the analysis of a drug product and its major degradants. In addition to

specificity, precision and the quantitation limit were also evaluated. Specificity was

evaluated using photodiode array peak purity; Table 9.1 summarizes the precision

results, and Table 9.2 the results from the determination quantitation limit. Figure 9.1

illustrates the actual separation at the quantitation limit used to verify the calculated

quantitation limit.

0.007

4

4.531

0.006

3

0.005

2.893

0.004

0.003

2

0.002

2.621

1

1.912

0.001

0.000

0.50

1.00

1.50

2.00

2.50

Minutes

3.00

3.50

4.00

4.50

5.00

FIgure 9.1

Verification of compendial procedure quantitation limits. Separation was

performed on an Alliance 2695 Separations Module (Waters, Milford, Massachusetts) using

a 4.6 by 100 mm 3.5-µ Xterra RPC18 column at 34°C. Mobile phase A was 10 mm pH 9.0

ammonium carbonate, B was methanol run at a 15%-90% B linear gradient over 5 min at 1.0

mL/min. A 20-µL injection and UV detection at 280 nm were also used. Peaks are in order:

(1) NTAP (highlighted in red), (2) ACBS, (3) HCT, and (4) TMT.