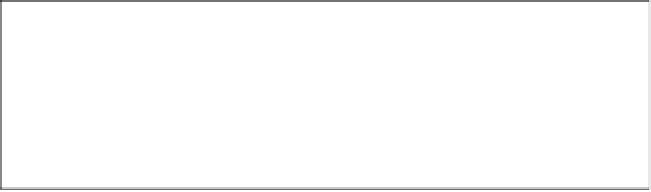

Chemistry Reference

In-Depth Information

UCL

Target

LCL

2

4

6

8

10

12

14

16

Run Number

FIgure 6.3

Typical control chart illustrating OOS results. Charts such as this can be

used to monitor for OOS results. By setting an upper control limit (UCL) and a lower con-

trol limit (LCL) around a target or average value according to specifications, OOS samples,

injections, batches, etc., can be easily observed.

outside the specification or acceptance criteria established in new drug applications

(NDAs), official compendia, or by the manufacturer” [15]. Control charts, such as

the example shown in Figure 6.3, can be used to easily inspect for OOS results.

OOS results can also observed, for example, in chromatography, from system suit-

ability results. Once an OOS result is obtained, an investigation must be launched

to determine the cause, and each step of the investigation must be documented. The

first phase of the investigation should include an initial assessment of the accuracy

of the data, before test solutions are discarded. It is the responsibility of the analyst

to review the data for compliance with specifications, and in cases where unexpected

results are obtained and no obvious explanation exists, retain test solutions, and

inform the supervisor. The supervisor's assessment should be objective and timely,

and include the following steps:

1. Discussing the test method with the analyst to confirm that the proper pro-

cedure was performed.

2. Examine the raw data, to identify potentially anomalous or suspect information.

3. Confirmation of instrument performance by reviewing qualification and

system suitability data.

4. Verify that proper reference standards, solvents, reagents, and other solu-

tions were used, and that they meet quality control specifications.

5. Compare the test method performance to ensure that it is performing to the

standard expected based on method validation data.

6. Documented evidence of the assessment.

Examining retained samples promptly is important to facilitate assigning a cause

to OOS results. For example, reinjection where a transient instrument malfunction

is suspected can provide strong evidence to rule out sample or sample preparation

anomalies. However, laboratory error should be relatively rare. Frequent errors sug-

gests inadequate training, poorly maintained or calibrated instruments, or careless

work. Whenever laboratory error is identified, corrective action should be taken to

prevent the problem from reoccurring.