Environmental Engineering Reference

In-Depth Information

6

5

4

7

1

8

2

3

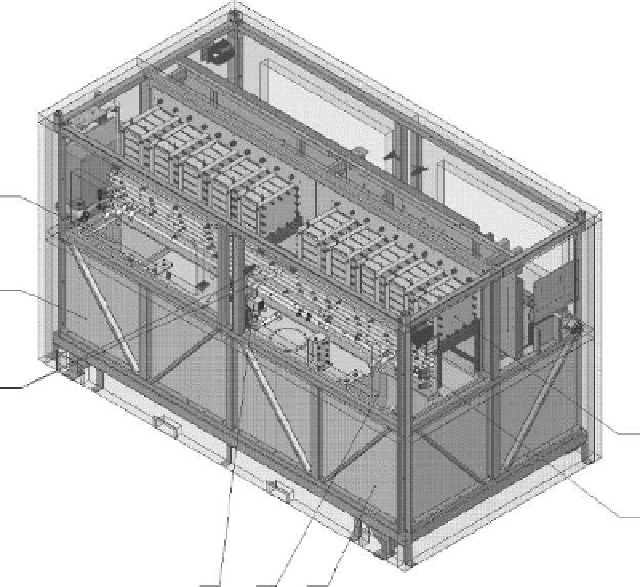

FIGURE 6.7

Fluid thermal safety system of Cellstrom's FB10/100. 1. Fluid lines. 2. Positive electrolyte

pumps. 3. Positive electrolyte tank. 4. Return lines. 5. Negative electrolyte tank. 6. Negative

electrolyte pumps. 7. Stacks (also called cell stacks or modules). 8. Rebalance valve. (From

html://www.cellstrom.com)

drainage system. Leakage from the main tank is minimized by a secondary

containment device containing leakage sensors. In addition, because the lines

are kept at pressures of 1 bar above atmosphere, leakage in the lines will not

cause significant spraying. As with all batteries containing water, hydrogen

evolution must be monitored to prevent potential explosions. Fortunately the

amount of hydrogen produced by this system is very small and is easily col-

lected and vented from the tanks.

The FB10/100 is an environmentally friendly system because it contains no

heavy metals. If the electrolyte is kept free of contamination, it can be reused

indefinitely. In addition, 99.9% of the plastics used are non-halogenated and

individual components can be replaced without the need to discard large

components.

Finally the system was designed to require minimum maintenance. The

FB10/100 has a design life of 20 years. While some of the stacks and pumps

may have to be replaced during that lifetime, the fluid and electrical systems