Environmental Engineering Reference

In-Depth Information

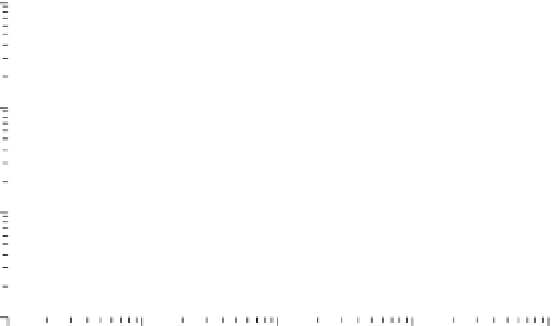

1000

6

IC engine

Fuel cells

4

100 h

EV goal

2

Li-ion

PHEV-40 goal

100

PHEV-10 goal

6

Ni-MH

4

Lead-acid

HEV goal

2

10 h

10

Capacitors

6

4

36 s

1 h

0.1 h

2

3.6 s

1

10

0

10

1

10

2

10

3

10

4

Specific Power (W/kg)

Acceleration

FIGURE 6.6

Plot of energy versus power for various energy systems. (From http://berc.lbl.gov.venkat.

Ragone-consruction.pps)

for diverse applications. This means that a VRB system can produce more

kilowatts of power simply by resizing the stacks and/or supply more energy

by increasing the size of the electrolyte storage tanks. The system theoreti-

cally has no limit to the amount of energy it can provide.

One may therefore ask, “Given all these advantages, why don't we see

more VRBs in operation?” The answer mainly involves energy density, size,

cost, possible irreversible precipitation of V

2

O

5

, and the infancy of the tech-

nology that makes most companies hesitant to invest in technology that has

not been fully tested. The energy density of a VRB is limited by V

2

0

5

and

has been measured to be ~167 Wh/kg. Figure 6.6 provides a comparison of

energy densities of other systems. For example, a 600-MWh vanadium redox

flow battery system would require 30 million liters of electrolyte. If stored in

6-m high tanks, its footprint would be the size of a football field. In general,

the following conditions must be met for the operation of vanadium redox

flow cells:

• Electrodes require high electric conductivity and good wettability.

• Charging voltage must be limited to a maximum of 1.7 V to avoid

damage to the carbon current collectors.

• Good electrical contact to the bipolar plates and current collectors is

essential and best achieved when the activation layers are thermally

bonded to the current collector.

• Access of oxygen to the negative electrolyte compartment must be

avoided.