Environmental Engineering Reference

In-Depth Information

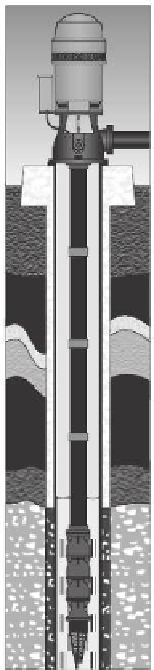

FIGURE 4.7

Example of submersible vertical turbine pump. (Figure courtesy of American Turbine Vertical

Turbine and Submersible Pumps. http://americanturbine.net/sites/americanturbine.net/files/

brochures/vertical-turbine-submersible-pump-brochure.pdf)

be capable of operating in reverse as a turbine at efficiencies in the range

of 65 to perhaps 85%.

10

This method is proposed as a preferred option for

the aquifer UPHES situation because it uses existing technology, is commer-

cially available, and represents a low cost solution. Because of the difficulty

in predicting turbine performance of a specific centrifugal pump, testing is

required to characterize the flow capability, water velocity range, and tur-

bine efficiency. The selected centrifugal pump design must employ a keyed

shaft to accommodate shaft torque in either direction.

Centrifugal motor pumps are commonly used for pumping water in many

situations. They are available in submerged or nonsubmerged designs, with

a wide range of available head ratings, flow ratings, and power ratings for

commercial versions. These units are commonly centrifugal or vertical tur-

bine designs, integrated with AC induction motors. The industry standard