Information Technology Reference

In-Depth Information

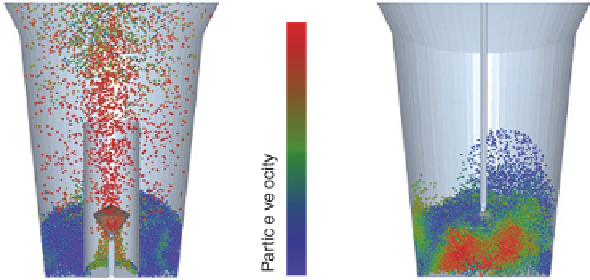

Particle positions and velocity distributions inside:

(a) Wurster-coater: and (b) top-spray granulator, at the

simulation time t = 1.4 s (reprinted from Fries et al.,

2011; with permission from Elsevier)

Figure 7.16

then in the Wurster granulator. In order to investigate the effects of

particle and fl uid dynamics on particle wetting, the residence time of the

particles inside the spray zone was monitored. The Wurster granulator

was characterized by a narrow residence time distribution, resulting in

homogeneous particle wetting, while the top-spray granulator was

characterized by wide residence time distribution, due to the irregular

particle motion. It was shown that the velocity of the air injected via the

nozzle and position of the draft tube in the Wurster granulator can affect

fl uid and particle dynamics.

Chua et al. (2011) used theoretical analysis coupled with CFD

simulations to predict granule-granule and droplet-granule collision

rates of fl uidized bed melt granulation in a top-spray granulator. CFD

simulations provided interesting information about hydrodynamics in

the region around the spray nozzle. Higher granular temperature was

observed around the spray nozzle, indicating higher collision rates in this

region (Figure 7.17). Due to the atomizing air fl ow effects, granules

within the spray zone are rapidly pushed towards the bottom, resulting

in solids concentrated at the walls. The range of granule-granule and

droplet-granule collision rates was determined, and droplet-granule

collision was found to be much faster, but slowed exponentially when

moving away from the spray nozzle. The authors concluded that results

of this study, together with time scale analysis of droplet spreading and

solidifi cation, may improve understanding of the events occurring during

Search WWH ::

Custom Search