Information Technology Reference

In-Depth Information

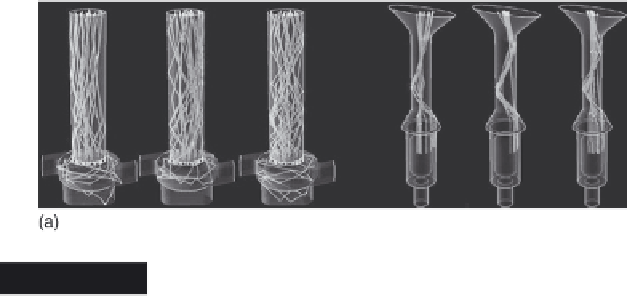

Carrier particle trajectory inside the inhaler at 60 L/min

(from left, d

particle

= 32, 108, and 275 μm): (a) Aerolizer®,

(b) Handihaler® (reprinted from Donovan et al., 2012;

with permission from John Wiley & Sons)

Figure 7.8

and particles are accelerated and directed towards the inhaler wall and

then towards the inhaler exit, without any swirling motion. It was

observed that the number of particle-inhaler collisions is more dependent

on carrier particle size in the case of the Aerolizer

®

, than in case of the

Handihaler

®

, with a greater number of collisions when larger carrier

particles were used. This was attributed to the presence of the swirling

motion and longer residence time inside the mouthpiece of the Aerolizer

®

.

Furthermore, the performance of the Aerolizer

®

was infl uenced by carrier

particle morphology, while performance of the Handihaler

®

was relatively

independent of surface roughness. Coupling the CFD simulations with

in

vitro

results, the authors concluded that impaction-based forces are not

the dominant mechanism in drug detachment from carrier particles in the

Handihaler

®

, in contrast to the Aerolizer

®

, and therefore both physical

properties of the carrier and the predominant detachment mechanism

have to be taken into account when analyzing DPI performance.

7.3.2 Dissolution apparatus hydrodynamics

Since the 1960s and 1970s, when the importance of dissolution tests in

drug quality control assessment was recognized and extensive work was

done on development and standardization of dissolution apparatus, until

nowadays dissolution testing has become an indispensable tool for

quality control of various dosage forms, and the fi eld of its possible

applications has been considerably expanded (Dressman and Krämer,

2005). Dissolution testing is widely used in the pharmaceutical industry

for optimization of formulation, testing of batch-to-batch reproducibility,

Search WWH ::

Custom Search