Civil Engineering Reference

In-Depth Information

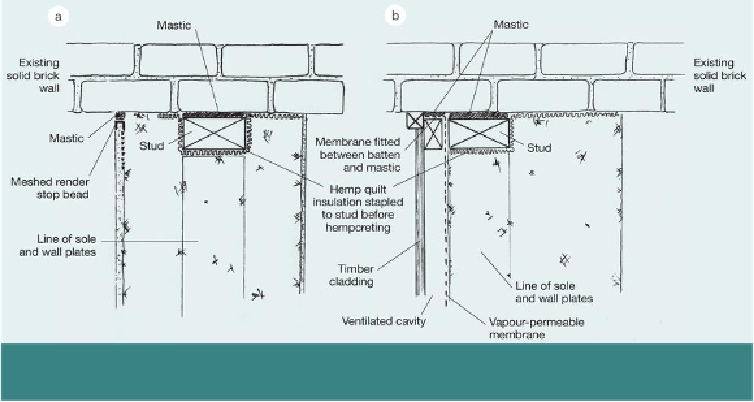

Figure 18.

Plan view: methods of achieving airtightness at junctions between a hempcrete wall and

a masonry wall, for (a) a rendered wall; (b) a clad wall.

Rather than trying to achieve a single solution to the problem, a more fail-safe approach

would be to consider the airtightness of each element joining the brick wall individually.

These elements will usually be a timber-frame stud, the hempcrete and the external finish

(lime render or cladding), as shown in Figure 18.

The timber stud could be sealed to the wall using expandable tape stuck to the back of the

stud before it is fixed to the wall. This will slowly expand once the stud is fixed, filling the

gaps that inevitably occur when fixing a flat material to a brick wall. However, these tapes

are made of synthetic materials and little information exists about their longevity, so they

may not constitute a robust solution to airtightness in the long term. The same effect can

be achieved by the addition of a natural mastic sealant prior to fixing the stud. Environ-

mentally sustainable mastics include burnt sand or linseed oil mastic sealant, which can be

used to good effect here.

Search WWH ::

Custom Search