Civil Engineering Reference

In-Depth Information

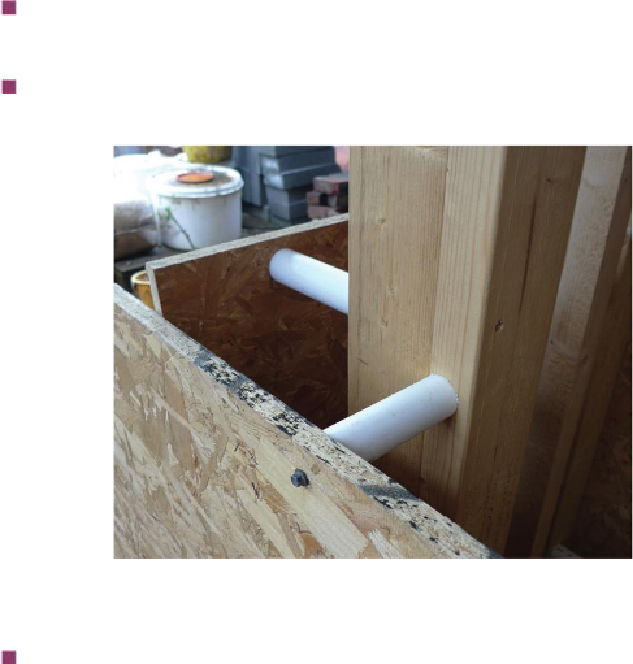

Tighten the fixings on the first board in the new run, and check it again for plumb and

square at the corner (using a level on both faces, and a square outside and inside the

corner formed by the boards), adjusting as necessary.

Continue with the new run, working off this first board.

Shuttering for an external corner.

Corners internally (Method 1):

Cut the two boards that run into the corner exactly to length, so that they butt up

against each other to form a corner that sits exactly the right distance from the frame.

Where possible, ensure that the factory-cut ends are used in the corner, as they will be

easier to butt up square against each other.

Obviously the boards cannot be screwed to one another as is done externally, as this

would involve screws being put in from inside the void, which is later filled with

hempcrete, making removal of the screws impossible. Instead, the normal fixings, i.e.

screws and spacers, on each board should hold the two boards in the right place (this

doesn't happen externally, as the external boards extend past the frame).

If it is felt necessary to adjust the position of the boards where they meet at the corner,

this can be done with a couple of heavy-duty screws diagonally from the corner of the

shuttering into the corner post (see

Figure 10

opposite). In this case, you might need

Search WWH ::

Custom Search