Civil Engineering Reference

In-Depth Information

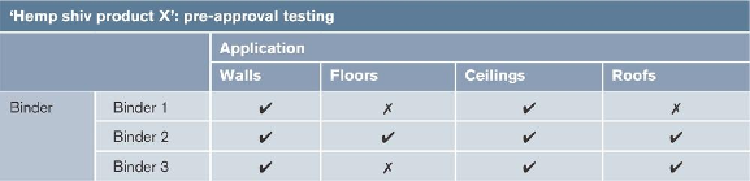

information, so that builders know whether a particular hemp shiv is suitable for use with

a particular binder in a given application, as in the hypothetical example shown in the table

below.

The UK hempcrete market is still some way from such a level of cooperation and flexib-

ility, but it is to be hoped that as the market continues to increase and the marketplace for

binders and shiv suppliers opens up, a time will come when UK builders have access to a

similar level of information about the products available.

Variations for different applications

The ratios of hemp:binder:water required when mixing hempcrete vary slightly depending

on which binder is being used, so the manufacturer's guidelines should always be fol-

lowed. It is important to adhere to the exact ratios, and mixing instructions, because having

the right proportions of binder, hemp and water is critical in ensuring that the binder has

enough water to set it, despite the tendency of the dry hemp shiv to 'compete' for the water

Example of flexible product testing regime carried out for the French

market

The 'standard' hempcrete mix can, however, be varied slightly in the proportion of binder

to hemp shiv, as advised by the binder manufacturer, in order to produce hempcrete that is

more suitable for a particular application. The mix ratio required to make hempcrete for a

wall is usually seen as the standard mix of a binder manufacturer.

Increasing the amount of binder for the same amount of hemp shiv produces a higher-dens-

ity mix, with greater structural integrity and thermal mass but reduced insulation value:

Search WWH ::

Custom Search