Geoscience Reference

In-Depth Information

and isotropic hydrated calcium silicate gel (C-S-H), which

is also referred to as 'tobermornite gel'. Within this are

embedded crystallites of portlandite (calcium hydroxide,

approximately 10%) and residual unhydrated cement

grains. In thin section, portlandite (Ca(OH)

2

) is visible in

the cement matrix as anhedral or euhedral crystallites,

plates or short prisms, up to 100 μm in size. They are

colourless in plane-polarized light and in cross-polarized

light they are highly birefringent and stand out against

almost isotropic uncarbonated gel. Over time (years to

decades) the cement matrix gradually reacts with the

atmosphere causing carbonation which alters the matrix

to crystalline calcium carbonate (see p. 96).

When describing the hardened cement matrix of

concrete samples the petrographer would normally

include the following. In hand specimen describe the

colour, distribution, relative hardness, and any evidence

of distress or deterioration Microscopically, the features

described should include the cement type, the nature of

relict cement grains, and the nature of portlandite

crystallites. Description of the relict cement grains and

portlandite crystallites should include size, relative

abundance, distribution, and shape. Size and relative

abundance can be described using the following

classifications:

• Size (average measurement across the grains or

crystallites):

• Small - <20 μm.

• Medium - 20-60 μm.

• Large - 60-100 μm.

• Very large - >100 μm.

• Relative abundance:

• Rare - only found by thorough searching.

• Sporadic - only occasionally observed during

normal examination.

• Common - easily observed during normal

examination.

• Frequent - easily observed with minimal

examination.

• Abundant - immediately apparent to initial

examination.

cement in concrete to be replaced by one or more mineral

additions. When combined with mineral additions,

cements are referred to as 'composite' or 'blended'

cements, in Europe and the USA respectively. Cost savings

gained from replacing cement clinker with industrial waste

products was the original reason for the development of

blended cements. Now mineral additions are used to

confer a range of performance benefits to the concrete mix

and to reduce the carbon footprint of concrete binders.

Mineral additions include a range of natural and

industrially manufactured materials that often exhibit

pozzolanic behaviour. The original pozzolana was volcanic

pumice from Pozzouli, Italy (

173

) that was used by the

Romans in lime concrete/mortar (see also p. 148). The

Romans discovered that when added to lime, the pozzolana

would allow it to set underwater, thus enabling marine

construction. This was due to the pozzolanic behaviour,

which involves a reaction between amorphous silica in the

pozzolana and calcium hydroxide in the lime binder or

cement clinker to form C-S-H. For certain pozzolanas, the

pozzolanic reaction is slower than Portland cement

hydration, with correspondingly lower rates of heat

liberation and strength gain. For Portland cement concrete,

this has the advantage of reducing the risk of early thermal

cracking but with the disadvantage of increasing the curing

time. The binder resulting from use of mineral additions is

often more durable as the pozzolanic reaction confers

reduced permeability (to aggressive agents) and a lower

content of calcium hydroxide (that could otherwise have

participated in deleterious reactions).

In modern concrete, the most commonly used

173

A

DDITIONS AND ADMIXTURES

Additions are inert, pozzolanic, or latent hydraulic

mineral powders, which are added at the mix.

Admixtures are chemicals added to concrete at the time

of mixing. These should not be confused with additives,

which are chemicals preblended with the cement or dry

cementitious mix. Other materials added to concrete

include fibres which are most commonly composed of

steel or plastic.

It is now common practice for a proportion of the

173

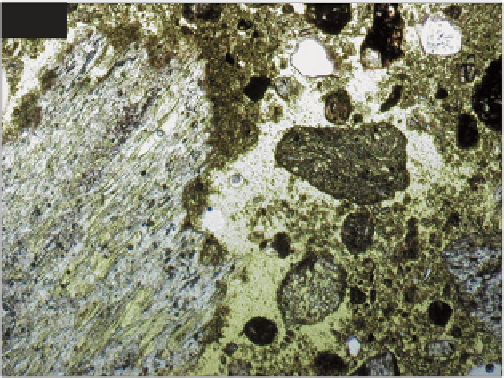

Natural pumice pozzolana from Bacoli, near

Pozzuoli (Italy); PPT, ×75.