Geoscience Reference

In-Depth Information

shows a fine aggregate that is contaminated with organic

material. Other forms of organic matter, such as coal and

lignite (see

217

), are undesirable in concrete aggregate as

they are weak, unsound, and can cause staining at

concrete surfaces. ASTM C33 limits the amount of coal

and lignite in concrete aggregate to 0.5% for concrete

elements with visible surfaces and 1% for hidden concrete.

Alkalis

- high levels of alkali metal ions (sodium and

potassium) can cause alkali-aggregate reaction (AAR) in

concrete (in the presence of reactive aggregate and

water). Salt-contaminated aggregates (marine aggregate)

can contain alkalis that can potentially contribute to

ASR. A number of common rock-forming minerals

(feldspars, phyllosilicates) contain appreciable alkalis and

in certain rare cases these have been released in concrete,

causing ASR (Goguel & Milestone, 2007). AAR is

discussed further in the following section and on

pp.109-114.

Sulfides and sulfates

- iron pyrite (iron sulfide) occurs

in some natural aggregate deposits such as the flint

gravels of southeast England. Some pyrites oxidize when

incorporated in concrete aggregate and may cause 'pop-

outs' and brown staining on concrete surfaces (see

216

).

Reactive pyritic aggregate particles can be distinguished

from unreactive ones by immersing them in a limewater

solution. Reactive pyrite particles will form a blue-green

gelatinous precipitate within 5 minutes that changes to a

brown colour within 30 minutes (Midgley, 1958). Sulfate

minerals are present in some aggregate resources and

when incorporated into concrete may cause sulfate

attack. In areas of the Middle East (French & Crammond,

1980) and in tropical coastal plains, sulfates commonly

occur in aggregate resources (

142

).

AGGREGATE FOR CONCRETE

AAR is the expansive reaction between alkali (sodium

and potassium) hydroxides in the pore solution of

concrete and minerals in the aggregates. These are

deleterious reactions that cause expansive cracking of

concrete structures, which detrimentally affects their

durability.

Petrographic examination is the ideal starting point

for the assessment of aggregates for alkali-aggregate

reactivity (Sims

et al

., 2002). In the United Kingdom,

concrete aggregate combinations are classified as being

of 'low', 'normal', or 'high' reactivity on the basis of their

petrographic composition. An aggregate or aggregate

combination is classified as being of low reactivity if it

comprises 97% or more of rock and mineral constituents

considered to be of low reactivity potential. An aggregate

or aggregate combination is classified as being of high

reactivity if it comprises either more than 10% crushed

greywacke or recycled demolition waste. An aggregate is

classified as being of normal reactivity if it cannot be

classified as being of low or high reactivity. Any

aggregate containing detectable opal or opaline silica

should not be classified and, in most circumstances,

should not be used. A list of aggregate and mineral types

142

142

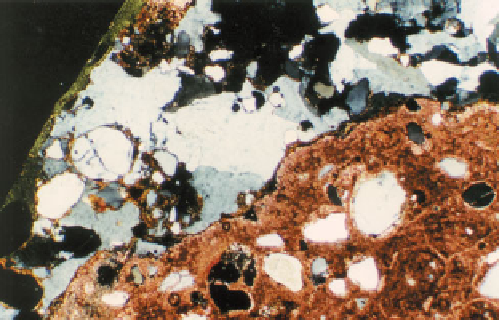

Limestone coarse aggregate particle (Saudi

Arabia) including the sulfate mineral gypsum (grey).

The thin section has been stained in accordance with

Dickson's method and the nonferroan calcite of the

limestone appears pink; XPT, ×35.