Geoscience Reference

In-Depth Information

M

IX PROPORTIONS

The standard wet chemical analysis involving acid

dissolution, for example in accordance with the BS 4551

method (British Standards Institution, 2005a) or the ASTM

C1342 method (ASTM International, 2005b), is unlikely to

be accurate for specialist mortars. These methods do not

take into account the potentially high contents of mineral

additions, calcite fillers, and organic polymers. As a more

accurate alternative, mix proportions can be determined

petrographically by point-counting the aggregate/cement/

void ratio, either in thin section or polished specimen.

received in the laboratory, an initial visual and low-power

microscopical examination is conducted to determine the

number of material types or layers, layer thickness, colour,

and the relative hardness, coherence, and bond strength (in

qualitative terms). High-power examination of thin section

specimens is then used to determine the grading and

mineralogy of any aggregate, binder type, the presence of

mineral additions/fillers/ fibres, and to screen the material

for evidence of defects or deterioration.

The analysis of specialist mortars presents a substantial

challenge owing to the wide range of both inorganic and

organic ingredients used. Some ingredients that may

comprise less than 1% of the mix and are difficult to detect

can have a profound influence on mix properties.

One approach is use separate techniques for the

inorganic from the organic ingredients. Optical microscopy

is usually most appropriate for the inorganic components,

supplemented by scanning electron microscopy if required.

Minerals that are difficult to distinguish optically may be

readily identified by XRD. Infrared spectrophotometry is

the most appropriate method of chemical analysis for

identifying organic components. Provided that the correct

solvent is used to extract the desired organic species from

the sample, this technique can rapidly determine the

generic organic materials type and provide clues for the

next stage of analysis. Pyrolysis-gas chromatography, gas-

liquid chromatography, and ultraviolet spectrophotometry

can all be used as complementary or stand alone analytical

techniques for isolating a specific organic ingredient (Hunt

& Everitt, 2001).

E

XAMPLES OF SPECIALIST MORTARS

The examples below are not intended to be a

comprehensive review of mortars for specialist

applications. Instead, selected materials have been used

to illustrate the range of ingredients that are likely to be

encountered in specialist mortars.

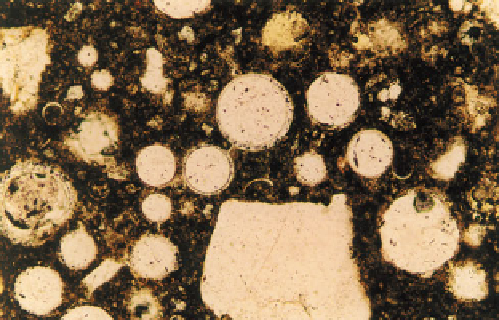

Figures

326

and

327

show a proprietary repair mortar

for concrete. It consists of fine (1.18 mm nominal

maximum sized) quartz fine aggregate bound by Portland

cement with polymer modification, a PFA mineral

addition, calcite dust filler, and polypropylene

microfibres. Figures

328

and

329

show a proprietary

mortar designed for setting fastenings in concrete. It

consists of 600 μm nominal maximum sized, quartz fine

aggregate bound by epoxy resin and Portland cement.

Figure

330

shows a proprietary grey-coloured

cementitious tile adhesive. It consists of quartz sand fine

aggregate, bound by Portland cement with a calcite dust

filler and latex bonding agent. Figures

331

and

332

show a brown-coloured cementitious tile adhesive,

comprising a mixture of Portland cement and calcium

326

327

326

Proprietary repair mortar for concrete, showing

fine aggregate particles (white) and cement matrix

(dark brown) with PFA (white spheres); PPT, ×150.

327

A cluster of polypropylene fibres (brightly

coloured) within a proprietary repair mortar for

concrete repair; XPT, ×150.