Geoscience Reference

In-Depth Information

comparison of the ingredients with a reference sample of

the specified plaster. In addition, samples can be screened

for impurities that can have a detrimental effect, such as

loam and clay which affect the setting time and final

strength.

A major drawback of gypsum binders is that they are

water soluble and are therefore only suitable for internal

work. The absorption of just 1% water can reduce strength

by up to half and long-term exposure breaks down the

interlocking structure of the gypsum crystals. They were

sometimes used externally on historic buildings as mortars

and renders, where they usually show signs of severe

weathering. Microscopical investigation of historic

gypsum mortar weathering typically shows the gypsum

binder dissolved away, with the remainder appearing

reprecipitated as larger crystals with a denser

microstructure (Middendorf, 2001). Observation using SEM

is required to study the morphology of the very fine

crystals found in gypsum plasters.

Workmanship issues that can be addressed include

checking that the plaster has been applied using the

specified number of layers, at the recommended

thickness. Finishing plaster can debond if the undercoat

has not had time to set, if it has an inadequate

mechanical key to the undercoat, or if a strong finishing

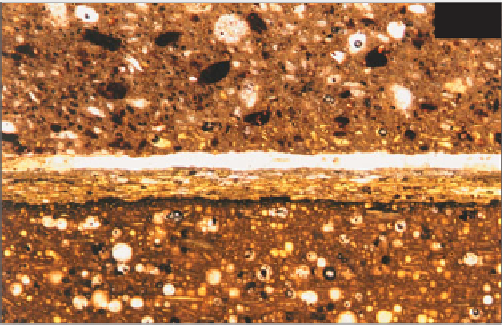

coat is applied to a weak undercoat. Figure

278

shows a

finishing plaster that has debonded from its plasterboard

background. Gypsum plasters are nonshrinking but may

suffer cracking for other reasons when subjected to

movement in excess of their strain capacity. Common

causes of cracking include background shrinkage (if the

background was very wet), base coat shrinkage (with

cement-based undercoats), cracks reflecting plasterboard

joints, and building movement. An unsatisfactory soft

powdery surface may result if the plaster dries out before

it has fully hydrated. This is more likely to happen if thin

coats are applied to a dry background, such as

plasterboard.

I

NTRODUCTION

Lime is formed by burning a source of calcium carbonate

(CaCO

3

), usually limestone or magnesian limestone,

between 850°C and 1200°C, driving off carbon dioxide

to form calcium oxide (CaO, quicklime). The calcium

oxide is then slaked with water (evolving heat) to form

calcium hydroxide (lime, Ca(OH)

2

). The slaking process

can produce dry lime hydrate powders or, if excess water

is used, lime putty. Lime mortars, plasters, and renders

are manufactured by mixing aggregate with a lime

product, either quicklime, lime hydrate powder, or lime

putty, adding water if required. Lime made from pure

limestone (nonhydraulic lime) sets by drying out and

then hardens wholly by absorption and reaction with

carbon dioxide, slowly to become calcium carbonate

again.

Burning

CaCO

3(s)

+ heat

→

CaO

(s)

+ CO

2(g)

Slaking

CaO

(s)

+ H

2

O

(l)

→

Ca(OH)

2(s)

Hardening

Ca(OH)

2(s)

+ CO

2(g)

→

CaCO

3(s)

+ H

2

O

(l)

Lime made from limestone containing siliceous

impurities has a degree of cementitious properties,

allowing it to set underwater (hydraulic lime). This occurs

as calcium and silica from within the impure limestone

react to form materials similar to those found in Portland

cement, such as dicalcium silicate, aluminate, and ferrite

phases, when the rock is calcined. The mechanism of

hardening of hydraulic limes is a combination of

carbonation and hydration of dicalcium silicate.

The principal applications of petrographic examination

to investigation of modern and historic lime mortars are:

• Identifying the type and source of aggregate.

• Identifying the type, origin, and manufacturing

process of the binder.

• Direct estimation of mix proportions.

• Enabling correction of mix proportions determined

by simple chemical analysis.

• Identifying and quantifying the presence of

inclusions, additives, and impurities.

• Assessing workmanship.

278

278

Natural gypsum finishing plaster (upper)

debonded from paper-faced plasterboard (lower). The

plasterboard comprises gypsum (brown) with

abundant entrained air voids (white, spherical). The

heavy paper facing is clearly visible running

horizontally across the centre of view; PPT, ×35.