Geoscience Reference

In-Depth Information

Synthetic resin floors do occasionally exhibit defects,

with the most common problem being detachment of the

resin topping due to poor preparation of the surface on

which it has been laid. Other issues involve cracks or

ripples reflecting cracks in the substrate, and cracks and

collapsed areas ('elephant's footprints') related to failure

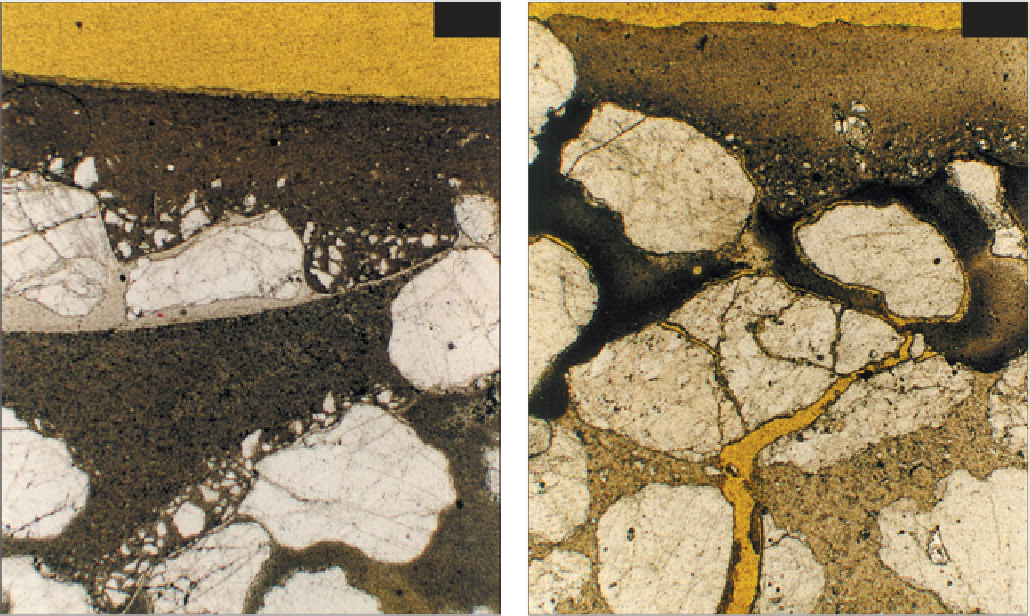

of the underlying screed. Figure

266

shows a multilayer

synthetic resin floor, which has cracked due to collapse

of the underlying sand:cement screed. This resin flooring

is a type 4 system that incorporates pigment and fine

quartz sand filler.

Osmotic blistering is a more unusual defect that involves

the formation of water-filled blisters on the surface of the

resin floor, where moisture has migrated by osmosis and

become trapped. Osmotic blisters are usually associated

with self-levelling types of resin floor (Pye & Harrison,

1997). The different types of synthetic resin used for resin

floorings have differing ranges of durability to temperature

conditions and chemical attack. It should be noted that all

of the synthetic resins will break down in the presence of

organic solvents and polyester resins are susceptible to

attack by alkaline solutions.

265

266

265

Section through multilayer synthetic resin floor

covering, showing three separate layers consisting of

quartz sand filler particles (white) bound by

pigmented resin (grey/brown). The aggregate within

the upper two layers appears to have settled out with

the coarsest particles sinking to the bottom; PPT, ×35.

266

Cracked multilayer synthetic resin floor covering.

The covering has cracked under load due to the

underlying screed being unacceptably weak. Quartz

filler particles appear white, pigmented resin appears

grey/brown, and the cracks are shown yellow; PPT,

×35.