Geoscience Reference

In-Depth Information

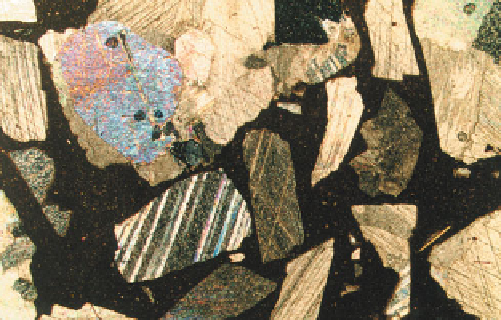

Granolithic screed is essentially concrete which contains

granite or other suitable crushed rock aggregate, to

provide wear resistance. Figure

260

shows the 'concrete-

like' appearance of a granolithic screed consisting of

granite coarse aggregate and natural sand fine aggregate,

bound by a Portland cement matrix; the screed exhibits

typical good compaction with very few air voids present.

Granolithic screeds usually provide durable floor finishes

but problems do occasionally occur. These typically

involve drying shrinkage cracking as granolithic screeds

are normally cement-rich and can have a high water

demand. Other defects may involve debonding and/or

curling of the screed, due to drying shrinkage and

possibly inadequate preparation of the base.

similar mixes to

in situ

terrazzo, but they are precast in

factories under controlled conditions and are now generally

preferred owing to their assured quality. Tile thickness

varies depending on the plan size with a common tile size

being 300 × 300 × 28 mm. The tile thickness may include

a nondecorative (and cheaper) backing mix.

In thin section, terrazzo typically has the appearance of

fine aggregate-deficient and cement-rich concrete

(cement:aggregate ratio typically 1:2.5-3.0). The cement

type is often white Portland cement and may include a

considerable quantity of pigment. Owing to the high

cement content it is relatively common to observe some

degree of microcracking of the cement matrix. Figure

261

shows the appearance of a cast

in situ

terrazzo consisting

of marble chips bound by white Portland cement. The fine

detail of the uncarbonated cement matrix is obscured by

the presence of pigment. Figure

262

shows a terrazzo floor

tile consisting of polishable crushed limestone coarse

aggregate and crushed decorative marble fine aggregate,

bound by a white Portland cement matrix. Again, the

detail of the uncarbonated cement matrix is obscured by

the presence of pigment and also a certain amount of

calcium carbonate dust.

Providing that it is correctly formulated, laid, and

maintained, terrazzo can provide a relatively hard and

durable floor surfacing. Some of the most common terrazzo

defects involve unsightly macrocracking that runs

perpendicular to the upper surface.

In situ

terrazzo is

Terrazzo is a special form of decorative concrete floor

finish that uses coloured cement (often white) and

decorative aggregate such as marble chips. The surface is

ground to expose the aggregate, which has a great

influence on the appearance.

Terrazzo may be laid

in situ

or, more commonly, as

terrazzo tiles.

In situ

terrazzo is normally laid on a high-

quality screed while the screed is still 'green', to a thickness

of not less than 15 mm. Once laid, coarse surface grinding

is undertaken after about 4 days, then filling and fine

grinding after a further 3 days. Terrazzo tiles consist of

260

261

260

Granolithic screed with crushed granite coarse

aggregate (upper left) and natural sand fine aggregate,

bound by an uncarbonated matrix of Portland-type

cement (black with brightly coloured 'specks'

comprising portlandite crystallites). Well compacted

with no air voids visible; XPT, ×35.

261

In situterrazzo floor finish, comprising crushed

marble chips (pink/light brown) bound by an

uncarbonated matrix of pigmented, white Portland

cement (dark brown); XPT, ×35.