Geoscience Reference

In-Depth Information

W

EATHERING BY LEACHING

,

FROST ATTACK

,

AND

SALT CRYSTALLIZATION

Dense, good-quality concrete is resistant to weathering

owing to its low permeability. However, most external

surfaces will eventually show evidence of deterioration

caused by natural weathering processes such as cyclic

wetting and drying, leaching, freeze-thaw mechanisms,

and salt crystallization.

Leaching of the cement matrix occurs when moisture

is able to pass through concrete. Calcium hydroxide

(portlandite) is leached from cement hydrates and may

be deposited within air voids or cracks (

199

).

Consequently, the leached cement matrix may appear

depleted of portlandite crystallites. Ettringite may also be

leaching from the cement matrix to line voids and cracks

(

200

). Abundant secondary deposits of ettringite

associated with cracks may be symptomatic of sulfate

attack of the aluminate phases, rather than just leaching

of existing ettringite. The importance of moisture

penetrating through concrete is frequently

underestimated as a cause of damage to concrete (French,

1991a). Major leaching will cause considerable

weakening of the cement matrix. Moisture is also

required for natural weathering processes such as frost

attack and salt crystallization and promotes deleterious

reactions such as sulfate attack and AAR.

In hardened concrete, cracks running perpendicular to

the surface (slabs and walls) may be caused by early age

thermal movement or drying shrinkage. A certain

amount of microcracking of the cement matrix is present

in all concrete and is considered to be a normal concrete

feature. The amount of microcracking caused by drying

shrinkage is related to the W/C of the concrete, with more

being present at higher W/C. Figure

197

shows a

shrinkage microcrack within a concrete bleeding channel

with localized high W/C. Microcracks generated by

shrinkage tend to meet at triple junctions in the paste, to

radiate from aggregate surfaces, run along parts of

aggregate surfaces, and initiate on voids (French, 1991a).

In reinforced concrete, expansion due to ASR or DEF

causes patterns of fine cracks on concrete surfaces, along

with cracking and microcracking at depth. The various

cracks may be filled with secondary deposits of alkali-

silica gel or sulfate minerals that may also exude on to

concrete surfaces. Reinforcement corrosion causes

cracking, spalling, and delamination of concrete often

with associated brown rust deposits. Crack patterns

associated with deleterious reactions are discussed later

in their respective sections. Cracking caused by structural

movement often runs through the aggregate particle as

well as the cement matrix. Figure

198

shows concrete

from a concrete cladding panel that cracked due to

flexural loading of the panel in service.

197

198

197

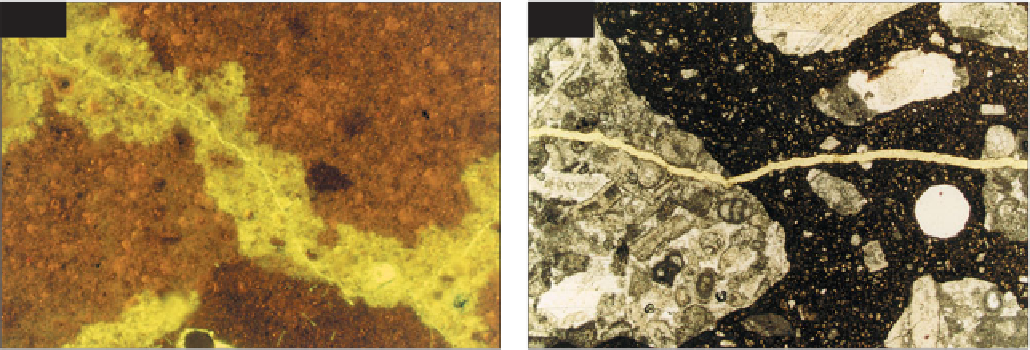

Close view of a microcrack (yellow) in the

cement matrix of structural concrete. The microcrack

has formed in a zone of high microporosity associated

with a bleeding channel (light green); UV, ×150.

198

Structural cracking of a concrete cladding panel.

A crack (yellow) runs both through the cement matrix

(dark brown) and limestone coarse aggregate particles

(light brown); PPT, ×35.