Civil Engineering Reference

In-Depth Information

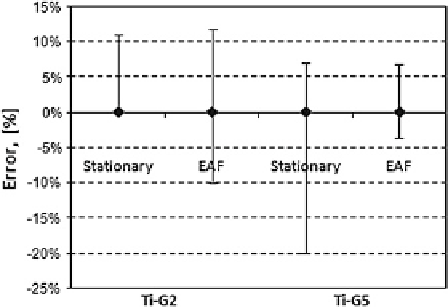

Fig. 4.17

Percent error

between model predictions

and experiments [

5

]. The

magnitude of the percent

error varied between the

material type and the test type

the larger

ξ

0

value, whereas the Ti-G5 EEC increased more consistently through-

out the length of the test, hence the larger

b

value.

The difference between model predictions and experiments was computed, and

the maximum and minimum differences as compared to the experimental meas-

urements of the temperature are presented in Fig.

4.17

. For most of the tests, the

model predicted the temperatures with less than 12 % error, while one of the tests

underestimated some of the values with about

−

20 %. Overall, the model predic-

tions agree well with the measurements, but refinement will be needed for greater

accuracy.

4.2.4 Thermal-Based EEC Conclusions

This section analyzed the thermo-mechanical aspects of the electroplastic effect. A

thermal model, accounting for material properties specifically for titanium alloys

various levels of plastic deformation, was verified using experimental EAF tests

[

4

]. The conclusions from this section are as follows:

• EAF reduced the low stress in both Ti-G2 and Ti-G5. Although just one current

was used, 300 A DC, based on previous work, similar results are expected for

different currents.

• To account for varying differences in thermal proiles between the conventional/

EAF tests, a new EEC was introduced, which was defined by a power law

relation.

• The EECs for the two Ti-grades were signiicantly different. This could be

because the grades of titanium were different. Ti-G2 is a single phase poly-

crystalline material, and Ti-G5 is a dual-phase alpha-beta alloy. For Ti-G2, the

electrons were able to travel easier because they only had to move through one

phase. This can be seen by noticing the steeper and higher EEC for Ti-G2 com-

pared to Ti-G5.