Civil Engineering Reference

In-Depth Information

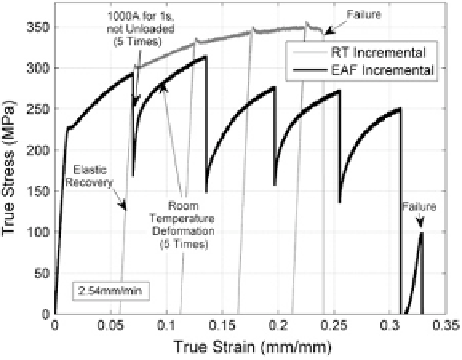

Fig. 3.6

Experimental flow

stress results comparing RT

and EAF incremental forming

3.3.2 Electrical Current with Metal Deformation

A similar theory is presented for the application of an electrical current during the

deformation of a metal. As the current is applied during deformation, the local “hot

spots” created from greater electron scattering at defects significantly enhance the

vibrational energy in the surrounding area of the dislocation. This greater energy

surrounding the dislocation allows for enhanced mobility along the slip plane as

it can pass by lattice obstacles with less resistance. Thus, the dislocation has a

greater quantity of energy and can move under a lower required stress (i.e., exter-

nal required force for deformation is reduced). The lower required stress is what

is observed on a macroscale when forming using an applied electric current. Also,

for the other defects within the material (point and interfacial defects), they have

an increased vibrational energy surrounding them as a result of larger amount of

electron scattering. As a result, if dislocations interact or become piled up at these

defects, this additional energy from scattering may allow the dislocation to pass by

the obstacle, where it otherwise would have remained pinned.

Aside from the local “hot spots” at dislocations and defects, the surrounding

defect-free lattice and the overall material temperature is rising. This overall bulk

temperature rise translates to traditional elevated temperature effects on material

deformation (i.e., thermal softening).

The reduction in material strength was observed in the square wave EAF tests

(Appendix B, Figs. B.2-B.5) where the material stress was significantly reduced

during the application of the current. From the theory, it is proposed that the main

effect is a result of localized “hot spots” which significantly increase the mobility

of the dislocations. Additionally, some dislocation annihilation may occur during

the time the current is applied. From the microstructure analysis that is presented

in Chap.

8

, it was noted that the EAF tests had a reduced amount of twinning