Civil Engineering Reference

In-Depth Information

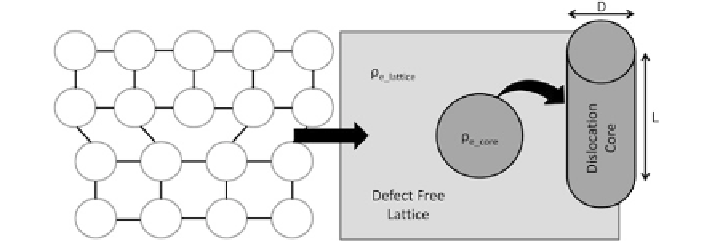

Fig. 3.1

Edge dislocation represented as a cylindrical dislocation core surrounded by a defect-

free lattice

transient wave of vibrational energy from the exterior surface. However, once the

material is completely heated and soaked at the elevated temperature, the vibra-

tional energy will be uniform within the material's lattice. This is one beneficial

aspect to using EAF over conventional elevated temperature forming.

Aside from using bulk observations to quantify this phenomenon [

2

-

4

], this

chapter introduces physics-based models to determine the significance of the

present electroplastic theories. Specifically, the transient energy provided to the

dislocation core and that transferred to the surrounding lattice are compared and

quantified. A schematic is shown in Fig.

3.1

where an edge dislocation is repre-

sented by a cylindrical dislocation core. The core geometry is characterized by a

right circular cylinder with a diameter (

D

) and length (

L

). The diameter used in

this work provides an equivalent area to the actual dislocation core area which is

represented by an elliptical cross section.

3.2 Previous Electroplastic Theories

The two primary theories for electroplasticity are localized heating at lattice defects

[

5

-

7

] and the electron wind effect [

8

-

10

]. The most recent work on electroplastic

theory suggests that the two phenomena occur simultaneously when an electric cur-

rent is applied during deformation [

4

]. This work compares the energy magnitude of

these two as related to the movement of a dislocation core in a metal's lattice.

3.2.1 Localized Heating

The localized heating is a result of increased scattering at defects, which creates

areas of greater atomic vibrations or “hot spots” (i.e., the Joule heating effect

increased at defect sites), whereas the electron wind effect is based on actual